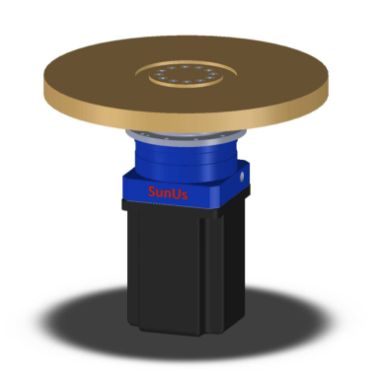

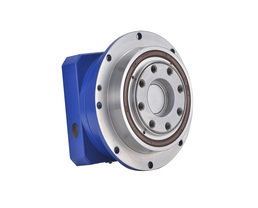

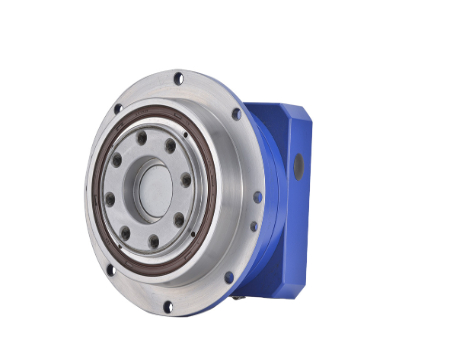

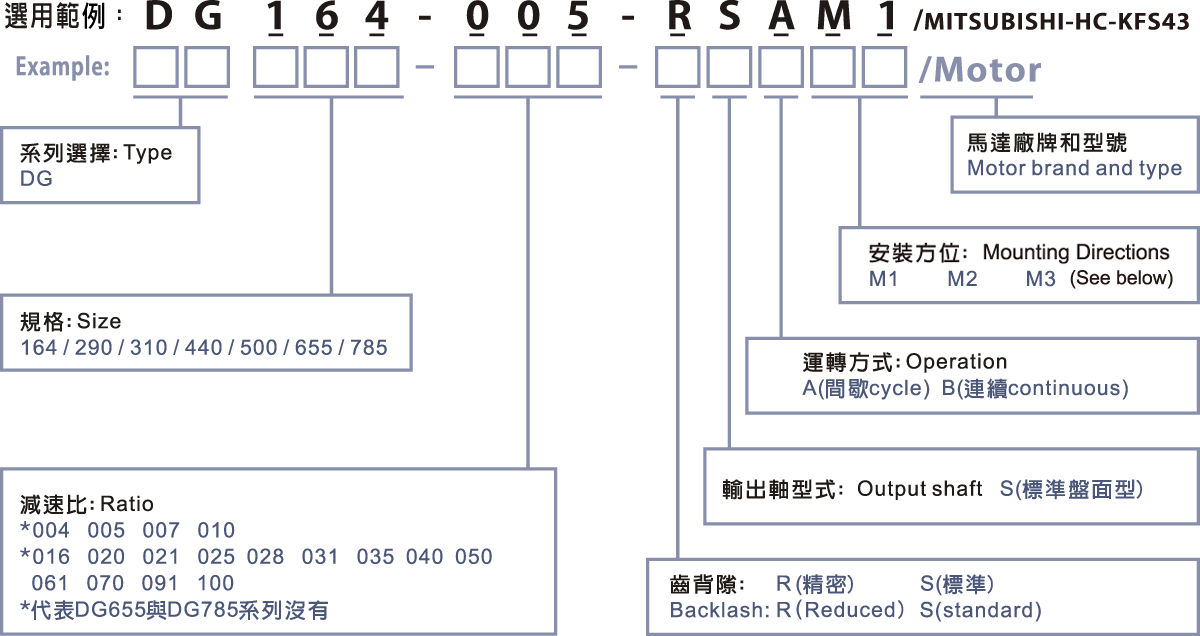

DG plate-design

Output shaft is designed with the flange design. Carrier and flange come in one-piece structure to ensure both the concentricity and bong strength of within the accessories. Compact design is perfect for the limited space.

| Precision Level |

|

|---|---|

| Torsional Rigidity |

|

| Price Range |

|

- Industry Applications

- CNC Machine Tools

- Special Purpose Machines (SPMs)

High positioning accuracy

- Precision grinding gear, smooth of gear surface, high accuracy of tooth profile.

- Backlash≦1 arcmin.<1 arcmin

Compact design

- Shorter than general shaft type reducer, suited on the limited space.。

Easy Installation

- For the modular input bushing and the changeable connecting plate according to the customer's brand of servo-motor.

Easy maintenance

- The gear with the deep carburizing heat treatment and precision grinding process, making its high stiffness and mesh accurate, prolonging the service life and low noise.

- Best-chosen German synthetic oil lubricant and protect the components inside the gearbox, oil-filled free

- Select superior quality, heat-resistance, wear-resistance seal, get the better sealing performance.

DG Technical Data (1-stage) Ratop 4/5/7/10

| Specifications | Ratios | DG164 | DG290 | DG310 | DG440 | DG500 | DG655 | DG785 | |

|---|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 4 | 58 | 145 | 360 | 710 | 1700 | 3600 | 6100 |

| 5 | 58 | 145 | 360 | 710 | 1700 | 3600 | 6100 | ||

| 7 | 55 | 125 | 335 | 650 | 1650 | 3350 | 5050 | ||

| 10 | 36 | 100 | 260 | 500 | 1300 | 2000 | 3500 | ||

| Emergency Stop Torque(2) T2Not | Nm | 4 | 115 | 310 | 700 | 1260 | 3250 | 8800 | 15000 |

| 5 | 115 | 310 | 700 | 1260 | 3250 | 8800 | 15000 | ||

| 7 | 105 | 270 | 625 | 1150 | 2800 | 8300 | 13650 | ||

| 10 | 100 | 220 | 500 | 900 | 2300 | 5000 | 10500 | ||

| Nominal Outout Torque T2N | Nm | 4 | 30 | 80 | 190 | 375 | 800 | 2250 | 3300 |

| 5 | 30 | 80 | 190 | 375 | 800 | 2250 | 3300 | ||

| 7 | 28 | 75 | 175 | 340 | 750 | 1830 | 2820 | ||

| 10 | 18 | 60 | 125 | 265 | 700 | 1050 | 1750 | ||

| Nominal Input Speed n1N | rpm | 4 | 3300 | 3000 | 2300 | 2000 | 1500 | 1200 | 1000 |

| 5 | 3300 | 3000 | 2300 | 2000 | 1500 | 1200 | 1000 | ||

| 7 | 4000 | 3200 | 2600 | 2500 | 2200 | 1700 | 1500 | ||

| 10 | 4000 | 3200 | 2600 | 2500 | 2200 | 1700 | 1500 | ||

| Maximum Input Speed n1Max | rpm | 4 | 6000 | 6000 | 4500 | 4000 | 3500 | 2500 | 2200 |

| 5 | 6000 | 6000 | 4500 | 4000 | 3500 | 2500 | 2200 | ||

| 7 | 6000 | 6000 | 4500 | 4000 | 3500 | 2500 | 2200 | ||

| 10 | 6000 | 6000 | 4500 | 4000 | 3500 | 2500 | 2200 | ||

| Axial Load(3) Famax | N | 4 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 |

| 5 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 7 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 10 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| Reduced Backlash | arcmin | 4 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 |

| 5 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 7 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 10 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| Standard Backlash | arcmin | 4 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 5 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 7 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 10 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Torsional Rigidity | Nm/arcmin | 4 | 12 | 32 | 83 | 155 | 580 | 950 | 1380 |

| 5 | 12 | 32 | 83 | 155 | 580 | 950 | 1380 | ||

| 7 | 12 | 32 | 83 | 155 | 580 | 950 | 1380 | ||

| 10 | 12 | 32 | 83 | 155 | 580 | 950 | 1380 | ||

| Efficiency with Full Load | % | 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| Service Life LH2 | h | 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Weight | kg | 4 | 1.6 | 4.0 | 7.0 | 14.5 | 31 | 62 | 83.5 |

| 5 | 1.6 | 4.0 | 7.0 | 14.5 | 31 | 62 | 83.5 | ||

| 7 | 1.6 | 4.0 | 7.0 | 14.5 | 31 | 62 | 83.5 | ||

| 10 | 1.6 | 4.0 | 7.0 | 14.5 | 31 | 62 | 83.5 | ||

| Noise Level(4) | dB | 4 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 5 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 7 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 10 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| Permissble Gear Reducer Temp. | °C | 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Protection Class | 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Lubrication | 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Mass Moments of Inertia | kg‧cm2 | 4 | 0.32 | 0.65 | 4.40 | 9.10 | 30.45 | - | - |

| 5 | 0.31 | 0.63 | 4.33 | 8.90 | 28.85 | 52.92 | 108.05 | ||

| 7 | 0.29 | 0.62 | 4.25 | 8.52 | 28.15 | 40.06 | 100.20 | ||

| 10 | 0.28 | 0.60 | 4.23 | 8.45 | 27.77 | 39.52 | 97.80 | ||

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 rpm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm. 1-meter distance and free load operation.

• Ratio 4 is not available for DG655 and DG785.

• If any customized ratios are unavailable from above, please contac us for mot

• Consult us if your mode is continuous operation.

DG Technical Data (2-stage) Ratio 16~100

| Specifications | Ratios | DG164 | DG290 | DG310 | DG440 | DG500 | DG655 | DG785 | |

|---|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 16 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 |

| 20 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 21 | 42 | 102 | 310 | 610 | 1400 | 3450 | 5050 | ||

| 25 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 28 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 31 | 42 | 115 | 300 | 630 | 1600 | 3600 | 6000 | ||

| 35 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 40 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 50 | 58 | 145 | 360 | 760 | 1650 | 3600 | 6100 | ||

| 61 | 46 | 115 | 285 | 560 | 1400 | 2850 | 4820 | ||

| 70 | 55 | 130 | 335 | 700 | 1500 | 3350 | 5050 | ||

| 91 | 33 | 85 | 255 | 510 | 1310 | 2800 | 4810 | ||

| 100 | 36 | 100 | 260 | 550 | 1410 | 2800 | 4810 | ||

| Emergency Stop Torque(2) T2Not | Nm | 16 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 |

| 20 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 21 | 105 | 260 | 610 | 1050 | 2800 | 8300 | 12100 | ||

| 25 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 28 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 31 | 105 | 260 | 610 | 1100 | 2800 | 8500 | 14000 | ||

| 35 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 40 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 50 | 115 | 310 | 700 | 1260 | 3250 | 8500 | 14500 | ||

| 61 | 105 | 240 | 570 | 930 | 2700 | 7300 | 10500 | ||

| 70 | 105 | 270 | 625 | 1100 | 2750 | 8300 | 13650 | ||

| 91 | 100 | 220 | 490 | 850 | 2200 | 5000 | 10500 | ||

| 100 | 100 | 220 | 500 | 900 | 2300 | 5000 | 10500 | ||

| Nominal Outout Torque T2N | Nm | 16 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 |

| 20 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 21 | 30 | 82 | 175 | 360 | 860 | 2150 | 3300 | ||

| 25 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 28 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 31 | 30 | 72 | 180 | 370 | 1250 | 2250 | 3720 | ||

| 35 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 40 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 50 | 40 | 92 | 215 | 410 | 1080 | 2450 | 3800 | ||

| 61 | 32 | 72 | 175 | 370 | 1120 | 1620 | 2910 | ||

| 70 | 28 | 88 | 180 | 405 | 900 | 1830 | 2820 | ||

| 91 | 16 | 40 | 110 | 230 | 710 | 1600 | 2910 | ||

| 100 | 18 | 60 | 125 | 265 | 800 | 1600 | 2910 | ||

| Nominal Input Speed n1N | rpm | 16 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 |

| 20 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 21 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 25 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 28 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 31 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 35 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 40 | 4000 | 3500 | 2800 | 3000 | 2500 | 2000 | 1500 | ||

| 50 | 5000 | 4000 | 3000 | 3200 | 3000 | 2400 | 2000 | ||

| 61 | 5000 | 4000 | 3000 | 3200 | 3000 | 2400 | 2000 | ||

| 70 | 5500 | 4500 | 3500 | 3800 | 3300 | 2500 | 2200 | ||

| 91 | 5500 | 4500 | 3500 | 3800 | 3300 | 2500 | 2200 | ||

| 100 | 5500 | 4500 | 3500 | 3800 | 3300 | 2500 | 2200 | ||

| Maximum Input Speed n1Max | rpm | 16 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 |

| 20 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 21 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 25 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 28 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 31 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 35 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 40 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 50 | 6000 | 6000 | 5000 | 5000 | 3000 | 3500 | 3500 | ||

| 61 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 70 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 91 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| 100 | 6000 | 6000 | 5000 | 5000 | 4000 | 3500 | 3500 | ||

| Axial Load(3) Famax | N | 16 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 |

| 20 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 21 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 25 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 28 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 31 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 35 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 40 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 50 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 61 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 70 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 91 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| 100 | 1650 | 2200 | 4200 | 6150 | 10000 | 33000 | 50000 | ||

| Reduced Backlash | arcmin | 16 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 |

| 20 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 21 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 25 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 28 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 31 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 35 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 40 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 50 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 61 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 70 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 91 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| 100 | ≤2 | ≤1 | ≤1 | ≤1 | ≤1 | ≤2 | ≤2 | ||

| Standard Backlash | arcmin | 16 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 20 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 21 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 25 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 28 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 31 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 35 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 40 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 50 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 61 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 70 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 91 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 100 | ≤4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Torsional Rigidity | Nm/arcmin | 16 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 |

| 20 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 21 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 25 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 28 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 31 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 35 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 40 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 50 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 61 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 70 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 91 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| 100 | 12 | 32 | 83 | 155 | 565 | 900 | 1380 | ||

| Service Life LH2 | h | 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 21 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 31 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 61 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 91 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Efficiency with Full Load | % | 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 21 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 31 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 61 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 91 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| Weight | kg | 16 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 |

| 20 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 21 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 25 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 28 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 31 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 35 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 40 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 50 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 61 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 70 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 91 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| 100 | 1.7 | 4.2 | 7.2 | 15 | 35 | 60 | 80 | ||

| Noise Level(4) | dB | 16 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 20 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 21 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 25 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 28 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 31 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 35 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 40 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 50 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 61 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 70 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 91 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 100 | ≤60 | ≤62 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| Permissble Gear Reducer Temp. | °C | 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 21 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 31 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 35 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 61 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 91 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Protection Class | 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 21 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 31 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 40 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 61 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 91 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Lubrication | 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 21 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 31 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 61 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 91 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Mass Moments of Inertia | kg‧cm2 | 16 | 0.19 | 0.31 | 0.63 | 4.35 | 9.30 | - | - |

| 20 | 0.16 | 0.30 | 0.61 | 4.28 | 9.10 | 29.00 | 30.05 | ||

| 21 | 0.17 | 0.31 | 0.62 | 4.30 | 9.05 | 29.10 | 30.08 | ||

| 25 | 0.16 | 0.30 | 0.61 | 4.28 | 9.10 | 29.00 | 30.10 | ||

| 28 | 0.20 | 0.28 | 0.60 | 4.10 | 8.75 | - | - | ||

| 31 | 0.18 | 0.32 | 0.63 | 4.30 | 9.12 | 29.05 | 29.00 | ||

| 35 | 0.15 | 0.28 | 0.60 | 4.10 | 8.75 | 28.30 | 28.48 | ||

| 40 | 0.12 | 0.27 | 0.58 | 4.05 | 8.60 | - | - | ||

| 50 | 0.12 | 0.27 | 0.58 | 4.05 | 8.60 | 27.95 | 28.07 | ||

| 61 | 0.13 | 0.28 | 0.59 | 4.10 | 8.70 | 28.05 | 28.07 | ||

| 70 | 0.12 | 0.26 | 0.57 | 4.05 | 8.60 | 27.95 | 28.07 | ||

| 91 | 0.11 | 0.27 | 0.58 | 4.08 | 8.65 | 27.90 | 28.05 | ||

| 100 | 0.10 | 0.25 | 0.57 | 4.05 | 8.55 | 27.85 | 28.05 | ||

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 rpm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm. 1-meter distance and free load operation.

• Ratio 16/28/40 are not available for DG655 and DG785.

• If any customized ratios are unavailable from above, please contac us for more details.

• Consult us if your mode is continuous operation.

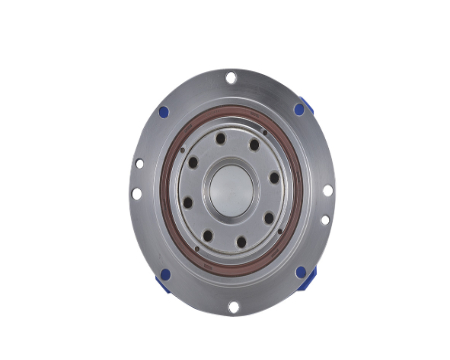

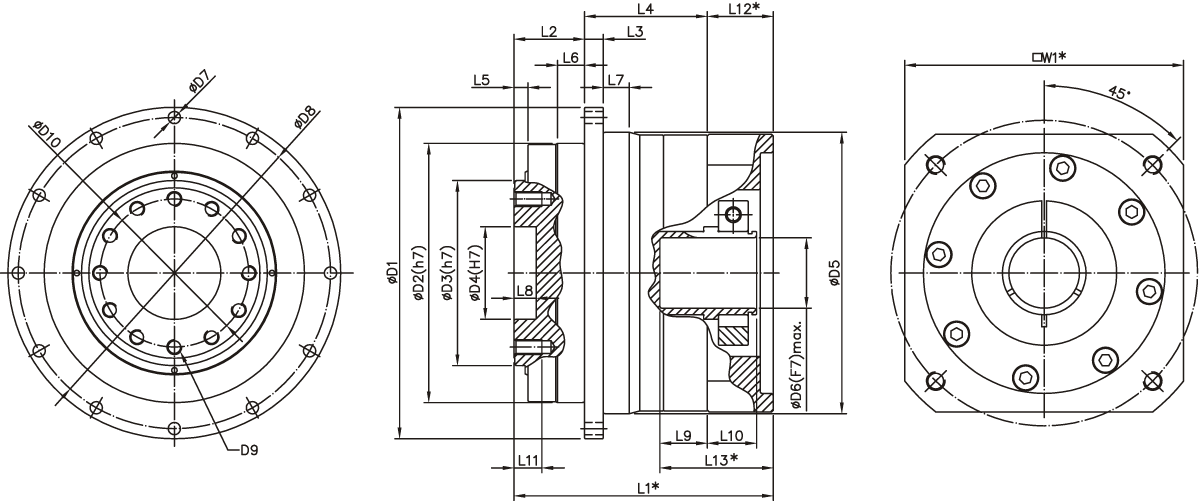

DG dimensions (1-stage ratio 4/5/7/10)[mm]

| Frame size | DG164 | DG290 | DG310 | DG440 | DG500 | DG655 | DG785 |

|---|---|---|---|---|---|---|---|

| ※□W1 min. | 70 | 95 | 120 | 152 | 210 | 190 | 240 |

| øD1 | 86 | 118 | 145 | 179 | 247 | 300 | 330 |

| øD2 (h7) | 64 | 90 | 110 | 140 | 200 | 255 | 285 |

| øD3 (h7) | 40 | 63 | 80 | 100 | 160 | 180 | 200 |

| øD4 (h7) | 20 | 31.5 | 40 | 50 | 80 | 100 | 100 |

| øD5 | 70 | 95 | 120.5 | 152.5 | 212.5 | 255 | 285 |

| øD6 (F7) max. | 14 | 19/24 | 32 | 38 | 48 | 55 | 60 |

| øD7 | 4.5 | 5.5 | 5.5 | 6.6 | 9 | 13.5 | 13.5 |

| øD8 | 79 | 109 | 135 | 168 | 233 | 280 | 310 |

| D9 | M5*P0.8 | M6*P1 | M6*P1 | M8*P1.25 | M10*P1.5 | M16*P2 | M20*P2.5 |

| øD10 | 31.5 | 50 | 63 | 80 | 125 | 140 | 160 |

| ※L1 | 82 | 109 | 133.75 | 140.2 | 180 | 229 | 248.5 |

| L2 | 19.5 | 30 | 29 | 38 | 50 | 66 | 75 |

| L3 | 4 | 7 | 8 | 10 | 12 | 18 | 20 |

| L4 | 40 | 51 | 71.25 | 69.2 | 84 | 81.5 | 123.5 |

| L5 | 4 | 7 | 7 | 7.5 | 8.5 | 13.5 | 16.5 |

| L6 | 8 | 10 | 10 | 18 | 23 | 28 | 35 |

| L7 | 7 | 8 | 9 | 14 | 15 | 20 | 21 |

| L8 | 8 | 12 | 12 | 12 | 16 | 20 | 20 |

| L9 | 9 | 15 | 30.5 | 29.2 | 37.5 | 44.5 | 47 |

| L10 | 18 | 22.5 | 22.5 | 25.8 | 45 | 40 | 39 |

| L11 | 7 | 10 | 12 | 15 | 20 | 25 | 30 |

| ※L12 | 22.5 | 28 | 33.5 | 33 | 46 | 47 | 50 |

| ※L13 | 31.5 | 43 | 64 | 62.2 | 83.5 | 91.5 | 97 |

※Actual dimensions marked above may vary from different servo motors.

We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

DG dimensions (2-stage ratio 16~100)[mm]

.jpg)

| Frame size | DG164 | DG290 | DG310 | DG440 | DG500 | DG655 | DG785 |

|---|---|---|---|---|---|---|---|

| ※□W1 min. | 70 | 95 | 100 | 130 | 150 | 210 | 210 |

| øD1 | 86 | 118 | 145 | 179 | 247 | 300 | 330 |

| øD2 (h7) | 64 | 90 | 110 | 140 | 200 | 255 | 285 |

| øD3 (h7) | 40 | 63 | 80 | 100 | 160 | 180 | 200 |

| øD4 (h7) | 20 | 31.5 | 40 | 50 | 80 | 100 | 100 |

| øD5 | 70 | 95 | 120.5 | 152.5 | 212.5 | 255 | 285 |

| øD6 (F7) max. | 14 | 19 | 24 | 32/38 | 38 | 48 | 48 |

| øD7 | 4.5 | 5.5 | 5.5 | 6.6 | 9 | 13.5 | 13.5 |

| øD8 | 79 | 109 | 135 | 168 | 233 | 280 | 310 |

| D9 | M5*P0.8 | M6*P1 | M6*P1 | M8*P1.25 | M10*P1.5 | M16*P2 | M20*P2.5 |

| øD10 | 31.5 | 50 | 63 | 80 | 125 | 140 | 160 |

| ※L1 | 108.5 | 139 | 152.75 | 187 | 208.5 | 300.5 | 310 |

| L2 | 19.5 | 30 | 29 | 38 | 50 | 66 | 75 |

| L3 | 4 | 7 | 8 | 10 | 12 | 18 | 20 |

| L4 | 63.5 | 81 | 96.75 | 118.5 | 125 | 187.5 | 190 |

| L5 | 4 | 7 | 7 | 7.5 | 8.5 | 13.5 | 16.5 |

| L6 | 8 | 10 | 10 | 18 | 23 | 28 | 35 |

| L7 | 7 | 8 | 9 | 14 | 15 | 20 | 21 |

| L8 | 8 | 12 | 12 | 12 | 16 | 20 | 20 |

| L9 | 15.5 | 14.5 | 20.5 | 30.5 | 28.5 | 38.8 | 38.8 |

| L10 | 18 | 21 | 21 | 22.5 | 26.5 | 33.2 | 33.2 |

| L11 | 7 | 10 | 12 | 15 | 20 | 25 | 30 |

| ※L12 | 22.5 | 28 | 27 | 30.5 | 33.5 | 47 | 45 |

| ※L13 | 38 | 42.5 | 47.5 | 61 | 62 | 85.2 | 83.8 |

※Actual dimensions marked above may vary from different servo motors.

We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

MACHINE TOOLS

- CNC Gantry Milling Machine / CNC Gantry Grinding Machine

- CNC Integrated Processing Machine / CNC Deephole Processing Machine

- CNC Floor Boring Machine / CNC Drilling Machine

- CNC Gantry Planing Mill / CNC Punching Machine

- CNC Heavy Duty Lathe (Horizontal or Vertical Spindle

SPECIAL PURPOSE MACHINES

- Packaging Machinery / Print Machine / Tapping machine

- Textile Machinery / Tube Bending Machine / CNC Press

- Woodworking Machine / Blow Molding Machine / Engraving Machine

- Filling Machine / Injection Molding Machine / Spring Machine

- Laser Cutting Machine / Laser Welding Machine

FACTORY AUTOMATION

- Semiconductor Machinery and Equipment / Photoelectric Panel Industry

- Gantry Loader / Automated Storage and Retrieval System

- Medical Industry / Metal Surface Treatment Equipment

High Torque Positioning System Applications

- Automatic Mechanical Device with Servo Motor Collocation

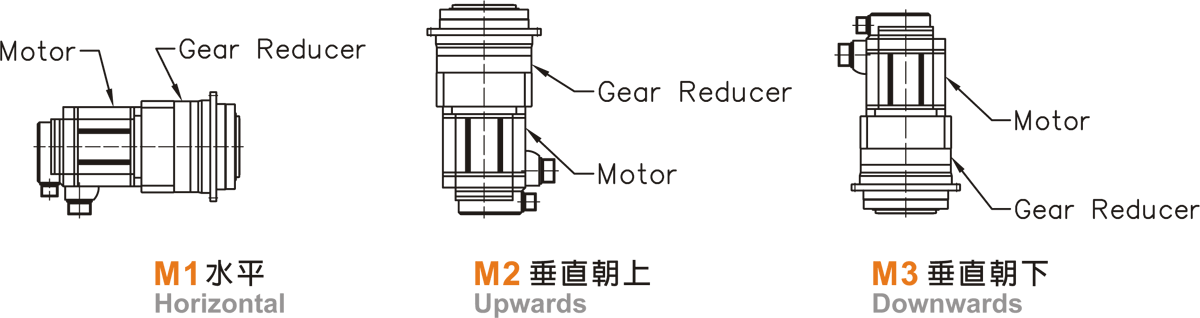

Mounting positions

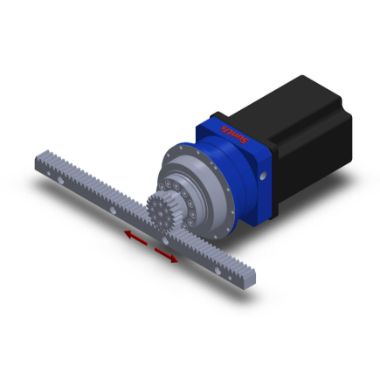

Rack & Pinion