Planetary gear reducers in application

2022/04/18

Planetary gear reducers, an indispensable and critical accessory for many equipment, feature small size, large torque, and smooth and long life.

It is essential for robot gear reducers to be of small size, large ratio and low backlash. Planetary gear reducers can be thought of as our joints. Flexibility and adaptability are what we desire in terms of the agile movement on the daily basis. Our expectations for them are beyond that and we aspire to continuous processing 24 hours a day and 365 days a year without any disruption or malfunction.

When it comes to durability, wind turbines remain functional every single day with the possibility of abrasion. It is, therefore, of importance for planetary gear reducers to be precise on the positioning accuracy and durable on the capability to resist harsh environments. After all, replacing a component at an altitude of more than 200 meters is not an easy task.

Do you think the environment that wind turbines function is harsh enough? An even worse condition exists when gear reducers for mining applications come into play. Has it ever occurred to you that these tunnels were excavated when you drive through these tunnels? Heavy-duty machinery, equipped with a cutter aiming to destroy sharp rocks, with a large disc onto its front end and a rotating disc to dig tunnels are called tunnel boring machines. 3-5 planetary gear reducers are installed to drive a slewing bearing so as to serve its purpose to propel the discs in the process of tunnel digging. While excavating, one could encounter high-pressure gas and liquids encompassed in the surrounding environment as well as hard rocks. Believe it or not, failure to perform processing resulting from the malfunction of planetary gear reducers under such an enclosed space would be the last thing one can think of. True as it may be, characteristics of planetary gear reducers for mining applications are of large torque output and should almost be “impenetrable and invincible”.

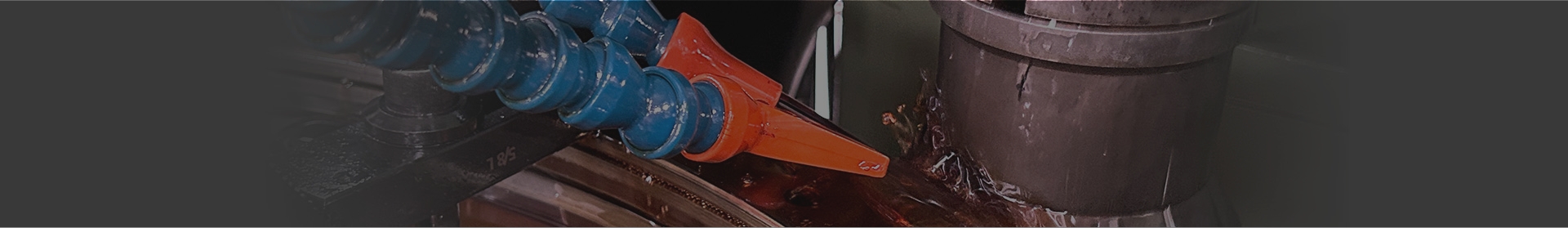

Whether it is wind turbines, robots or reducers, the parts that make up these devices need to be machined with precision CNC tools. Because of its common characteristics of high precision, low backlash and smooth operation, many large CNC machine tools are also our long-term clients of our planetary gear reducers. Engineers install and connect planetary gear reducers to servo motors in alignment with their axial. They set up servo controllers and conduct positioning processing. Selecting the suitable planetary gear reducers and accessory enables these large machine centres to achieve 0.01 mm high-precision positioning.

.jpg)

It is essential for robot gear reducers to be of small size, large ratio and low backlash. Planetary gear reducers can be thought of as our joints. Flexibility and adaptability are what we desire in terms of the agile movement on the daily basis. Our expectations for them are beyond that and we aspire to continuous processing 24 hours a day and 365 days a year without any disruption or malfunction.

When it comes to durability, wind turbines remain functional every single day with the possibility of abrasion. It is, therefore, of importance for planetary gear reducers to be precise on the positioning accuracy and durable on the capability to resist harsh environments. After all, replacing a component at an altitude of more than 200 meters is not an easy task.

Do you think the environment that wind turbines function is harsh enough? An even worse condition exists when gear reducers for mining applications come into play. Has it ever occurred to you that these tunnels were excavated when you drive through these tunnels? Heavy-duty machinery, equipped with a cutter aiming to destroy sharp rocks, with a large disc onto its front end and a rotating disc to dig tunnels are called tunnel boring machines. 3-5 planetary gear reducers are installed to drive a slewing bearing so as to serve its purpose to propel the discs in the process of tunnel digging. While excavating, one could encounter high-pressure gas and liquids encompassed in the surrounding environment as well as hard rocks. Believe it or not, failure to perform processing resulting from the malfunction of planetary gear reducers under such an enclosed space would be the last thing one can think of. True as it may be, characteristics of planetary gear reducers for mining applications are of large torque output and should almost be “impenetrable and invincible”.

Whether it is wind turbines, robots or reducers, the parts that make up these devices need to be machined with precision CNC tools. Because of its common characteristics of high precision, low backlash and smooth operation, many large CNC machine tools are also our long-term clients of our planetary gear reducers. Engineers install and connect planetary gear reducers to servo motors in alignment with their axial. They set up servo controllers and conduct positioning processing. Selecting the suitable planetary gear reducers and accessory enables these large machine centres to achieve 0.01 mm high-precision positioning.

.jpg)

Keyword Search

Category

Keywords

- Planetary gear reducers

- Small size and large torque

- Robot gear reducers

- Wind turbine

- CNC machining precision

Recommended

- Construction, principles and advantages of planetary gear reducers

- Root cause of abnormal noise in planetary gear reducers (2)

- Root cause of abnormal noise in planetary gear reducers (1)