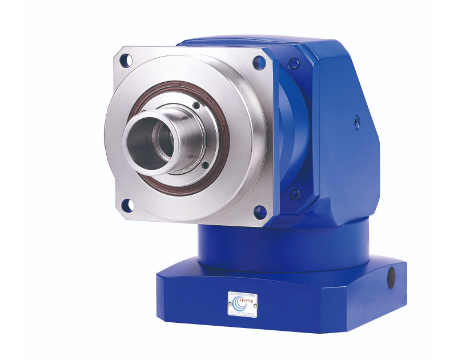

HGR hollow-shaft right-angle

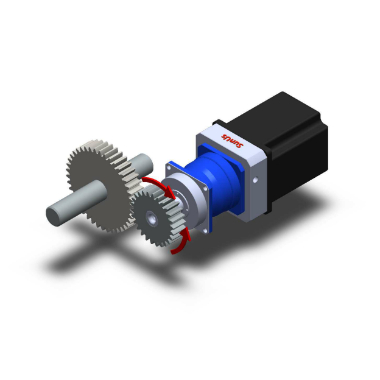

Hollow output shaft is designed with the installation of fewer teeth and compatible with a smaller servo motor. Less torque is required to start operation and produce higher economical benefits. Ball screws can be directly installed with planetary gear reducers to reach higher accuracy.

| Precision Level |

|

|---|---|

| Torsional Rigidity |

|

| Price Range |

|

- Industry Applications

- CNC Machine Tools

- Special Purpose Machines (SPMs)

Smooth operation and low noise

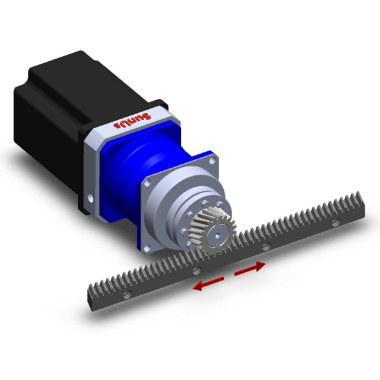

- Hardened and ground rack and pinion adopt helical and spur system.

Easy installation and weight saving

- Pinion and output shaft of reducer are connected with high stiffness coupling。

High radial and axial load

- Using high-quality taper roller bearing to strengthen the radial and axial load.

Rack and pinion can be adjusted to the best precision

- With eccentric plate and simplified structure could be adjusted the position of pinion easily.

High dynamics

- For an excellent design, high accuracy, and low moments of inertia.

High economical effect

- Low moment characteristics could select the smaller kilowatt servo motor, further carry the cost-down out.

Perfect for linear positioning

- Adopting ground rack and pinion; cumulative pitch error 0.03/1000mm

Long service life

- Well design and structure

- Using high-quality taper roller bearing

- High-quality German seal

- Harden and ground gear

- Best-chosen synthetic oil

HGR Technical Data (1-stage) Ratio 3~20

| Specifications | Ratios | HGR100 | HGR120 | HGR140 | HGR160 | HGR180 | HGR210 | |

|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 3 | 202 | 330 | 440 | 735 | 1055 | 1750 |

| 4 | 270 | 350 | 510 | 810 | 1300 | 2600 | ||

| 5 | 270 | 350 | 510 | 810 | 1300 | 2600 | ||

| 6 | 250 | 340 | 445 | 730 | 1180 | 2150 | ||

| 7 | 240 | 310 | 440 | 700 | 1130 | 1680 | ||

| 8 | 215 | 285 | 410 | 650 | 1040 | 1600 | ||

| 10 | 190 | 245 | 340 | 500 | 900 | 1500 | ||

| 14 | 240 | 310 | 440 | 700 | 1130 | 1680 | ||

| 20 | 190 | 245 | 340 | 500 | 900 | 1500 | ||

| Emergency Stop Torque(2) T2Not | Nm | 3 | 630 | 800 | 1100 | 1700 | 3000 | 6200 |

| 4 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | ||

| 5 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | ||

| 6 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | ||

| 7 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | ||

| 8 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | ||

| 10 | 500 | 650 | 900 | 1250 | 2220 | 3900 | ||

| 14 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | ||

| 20 | 500 | 650 | 900 | 1250 | 2220 | 3900 | ||

| Nominal Outout Torque T2N | Nm | 3 | 135 | 195 | 315 | 500 | 880 | 1200 |

| 4 | 185 | 240 | 340 | 550 | 1100 | 1900 | ||

| 5 | 185 | 240 | 340 | 550 | 1100 | 1900 | ||

| 6 | 155 | 210 | 320 | 460 | 845 | 1580 | ||

| 7 | 125 | 180 | 315 | 430 | 820 | 1050 | ||

| 8 | 120 | 175 | 293 | 410 | 755 | 1000 | ||

| 10 | 115 | 160 | 220 | 350 | 650 | 950 | ||

| 14 | 125 | 180 | 315 | 430 | 820 | 1050 | ||

| 20 | 115 | 160 | 220 | 350 | 650 | 950 | ||

| Nominal Input Speed n1N | rpm | 3 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 |

| 4 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 5 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 6 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 7 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 8 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 10 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 14 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| 20 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 | ||

| Maximum Input Speed n1Max | rpm | 3 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 |

| 4 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 5 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 6 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 7 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 8 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 10 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 14 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| 20 | 4500 | 4000 | 3500 | 3000 | 2500 | 2000 | ||

| Radial Load(3) Frmax | N | 3 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 |

| 4 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 5 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 6 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 7 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 8 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 10 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 14 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| 20 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | ||

| Axial Load(3) Famax | N | 3 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 |

| 4 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 5 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 6 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 7 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 8 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 10 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 14 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| 20 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | ||

| Micro Backlash | arcmin | 3 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| 4 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 5 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 6 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 7 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 8 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 14 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| 20 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||

| Reduced Backlash | arcmin | 3 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 |

| 4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 5 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 6 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 7 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 8 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 10 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 14 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| 20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤3 | ≤3 | ||

| Standard Backlash | arcmin | 3 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 |

| 4 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 5 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 7 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 8 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 10 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 14 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| 20 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ||

| Torsional Rigidity | Nm/arcmin | 3 | 23 | 35 | 50 | 95 | 150 | 220 |

| 4 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 5 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 6 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 7 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 8 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 10 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 14 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| 20 | 23 | 35 | 50 | 95 | 150 | 220 | ||

| Efficiency with Full Load | % | 3 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 6 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 8 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 14 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 20 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| Service Life LH2 | h | 3 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 6 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 8 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 14 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Weight | kg | 3 | 15.5 | 23 | 32 | 47 | 72.5 | 113 |

| 4 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 5 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 6 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 7 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 8 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 10 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 14 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| 20 | 15.5 | 23 | 32 | 47 | 72.5 | 113 | ||

| Noise Level(4) | dB | 3 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 |

| 4 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 5 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 6 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 7 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 8 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 10 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 14 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| 20 | ≤67 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ||

| Permissble Gear Reducer Temp. | °C | 3 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 6 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 8 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 14 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Lubrication | 3 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 6 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 8 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 14 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Protection Class | 3 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 6 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 8 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 14 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Mass Moments of Inertia | kg‧cm2 | 3 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 |

| 4 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 5 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 6 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 7 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 8 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 10 | 10.60 | 14.75 | 22.94 | 43.40 | 77.30 | 166.70 | ||

| 14 | 9.15 | 12.30 | 18.10 | 30.60 | 59.10 | 102.40 | ||

| 20 | 9.15 | 12.30 | 18.10 | 30.60 | 59.10 | 102.40 | ||

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 pm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm; 1-meter distance and free load operation.

• If any customized ratios are unavailable from above, please contact us for more.

• Consult us if your mode is continuous operation.

HGR Technical Data (2-stage) Ratio 12~200

| Specifications | Ratios | HGR100 | HGR120 | HGR140 | HGR160 | HGR180 | HGR210 | HGR240 | |

|---|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 12 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 |

| 15 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 16 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 20 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 25 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 28 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 30 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 35 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 40 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 50 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 60 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 70 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 80 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 100 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| 120 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 140 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 160 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 200 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| Emergency Stop Torque(2) T2Not | Nm | 12 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 |

| 15 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 16 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 20 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 25 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 28 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 30 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 35 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 40 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 50 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 60 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 70 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 80 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 100 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 120 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 140 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 160 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 200 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| Nominal Outout Torque T2N | Nm | 12 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 |

| 15 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 16 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 20 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 25 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 28 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 30 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 35 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 40 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 50 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 60 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 70 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 80 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 100 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| 120 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 140 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 160 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 200 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| Nominal Input Speed n1N | rpm | 12 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 |

| 15 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 16 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 20 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 25 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 28 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 30 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 35 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 40 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 50 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 60 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 70 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 80 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 100 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 120 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 140 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 160 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| 200 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 | 1500 | ||

| Maximum Input Speed n1Max | rpm | 12 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 |

| 15 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 16 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 20 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 25 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 28 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 30 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 35 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 40 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 50 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 60 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 70 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 80 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 100 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 120 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 140 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 160 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| 200 | 4500 | 4000 | 3500 | 3500 | 3500 | 2500 | 2500 | ||

| Radial Load(3) Frmax | N | 12 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 15 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 16 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 20 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 25 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 28 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 30 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 35 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 40 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 50 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 60 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 70 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 80 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 100 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 120 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 140 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 160 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 200 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| Axial Load(3) Famax | N | 12 | 5400 | 6700 | 9000 | 11300 | 1300 | 18000 | 27000 |

| 15 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 16 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 20 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 25 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 28 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 30 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 35 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 40 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 50 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 60 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 70 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 80 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 100 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 120 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 140 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 160 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| Micro Backlash | arcmin | 12 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

| 15 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 16 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 25 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 28 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 30 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 35 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 40 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 50 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 60 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 70 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 80 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 120 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 140 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 160 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| 200 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| Reduced Backlash | arcmin | 12 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 |

| 15 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 16 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 20 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 25 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 28 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 30 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 35 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 40 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 50 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 60 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 70 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 80 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 100 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 120 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 140 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 160 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| 200 | ≤6 | ≤6 | ≤6 | ≤6 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash | arcmin | 12 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 |

| 15 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 16 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 20 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 25 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 28 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 30 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 35 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 40 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 50 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 60 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 70 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 80 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 120 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 140 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 160 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| 200 | ≤8 | ≤8 | ≤8 | ≤8 | ≤7 | ≤7 | ≤7 | ||

| Torsional Rigidity | Nm/arcmin | 12 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 15 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 16 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 20 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 25 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 28 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 30 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 35 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 40 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 50 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 60 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 70 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 80 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 100 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 120 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 140 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 160 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 200 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| Efficiency with Full Load | % | 12 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 15 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 30 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 60 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 80 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 120 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 140 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 160 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 200 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| Service Life LH2 | h | 12 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 15 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 30 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 60 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 80 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 120 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 140 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 160 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 200 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Weight | kg | 12 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 |

| 15 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 16 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 20 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 25 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 28 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 30 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 35 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 40 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 50 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 60 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 70 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 80 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 100 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 120 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 140 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 160 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| 200 | 16.7 | 26.2 | 36 | 40 | 51.5 | 99 | 128 | ||

| Noise Level(4) | dB | 12 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 |

| 15 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 16 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 20 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 25 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 28 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 30 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 35 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 40 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 50 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 60 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 70 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 80 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 100 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 120 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 140 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 160 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| 200 | ≤60 | ≤70 | ≤70 | ≤70 | ≤71 | ≤73 | ≤73 | ||

| Permissble Gear Reducer Temp. | °C | 12 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 15 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 30 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 35 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 60 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 80 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 120 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 140 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 160 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 200 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Protection Class | 12 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 15 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 30 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 40 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 60 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 80 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 120 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 140 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 160 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 200 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Lubrication | 12 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 15 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 30 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 60 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 80 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 120 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 140 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 160 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 200 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Mass Moments of Inertia | kg‧cm2 | 12 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 |

| 15 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 16 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 20 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 25 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 28 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 30 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 35 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 40 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 50 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 60 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 70 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 80 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 100 | 10.60 | 14.75 | 22.95 | 22.95 | 22.95 | 77.30 | 77.30 | ||

| 120 | 9.15 | 12.30 | 18.10 | 18.10 | 18.10 | 59.00 | 59.00 | ||

| 140 | 9.15 | 12.30 | 18.10 | 18.10 | 18.10 | 59.00 | 59.00 | ||

| 160 | 9.15 | 12.30 | 18.10 | 18.10 | 18.10 | 59.00 | 59.00 | ||

| 200 | 9.15 | 12.30 | 18.10 | 18.10 | 18.10 | 59.00 | 59.00 | ||

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 pm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm; 1-meter distance and free load operation.

• If any customized ratios are unavailable from above, please contact us for more.

• Consult us if your mode is continuous operation.

HGR dimensions (1-stage ratio 3~20)[mm]

.png)

| Frame size | HGR100 | HGR120 | HGR140 | HGR160 | HGR180 | HGR210 |

|---|---|---|---|---|---|---|

| W1 | 100 | 120 | 140 | 160 | 182 | 210 |

| ※W2 mln. | 118 | 145 | 153.5 | 176 | 176 | 190 |

| D1 (g6) | 90 | 110 | 130 | 145 | 160 | 180 |

| D2 | 55 | 65 | 75 | 85 | 95 | 125 |

| D3 (H8) | 30 | 44 | 50 | 55 | 62 | 75 |

| D4 (H6) | 25 | 35 | 40 | 45 | 50 | 60 |

| D5 (H7) | 20 | 30 | 30 | 36 | 40 | 50 |

| D6 (H7) max. | 32 | 35 | 38 | 42 | 48 | 55 |

| D7 | 120 | 130 | 165 | 190 | 215 | 250 |

| D8 | 9 | 9 | 11 | 13 | 13 | 17 |

| D9 | 135 | 155 | 185 | 215 | 240 | 279 |

| L1 | 252 | 284.3 | 318 | 353.8 | 395.3 | 460 |

| L2 | 28 | 34 | 40 | 42 | 45 | 48 |

| L3 | 30 | 30 | 31 | 29.8 | 29.8 | 38 |

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 |

| L5 | 2 | 3 | 4 | 2.75 | 2.75 | 3 |

| L6 | 142 | 158 | 178 | 200 | 223.5 | 263 |

| L7 | 30 | 50 | 43 | 50 | 55 | 66 |

| L8 | 45 | 70 | 63 | 75 | 85 | 100 |

| C1 | 29 | 27.2 | 37.2 | 39.3 | 44 | 46.5 |

| C2 | 24.2 | 25.3 | 26.8 | 28 | 34 | 38.5 |

| C3 | 13.2 | 13.8 | 14.8 | 15.5 | 18.5 | 20.5 |

| ※C4 min. | 31 | 32 | 35 | 36 | 42 | 47 |

| ※C5 min. | 60 | 59.2 | 72.2 | 75.2 | 86 | 93.5 |

| ※C6 min. | 129.5 | 138.7 | 158.5 | 176.5 | 201 | 226 |

| ※C7 min. | 181.5 | 200.2 | 227.5 | 258.5 | 298 | 337 |

※此記號表示之尺寸視聯結之伺服馬達不同而有所變動。

本公司的產品不斷的研究﹑發展。上表所示之尺寸力求精準,若有不符,仍以實物為準,如需確實之尺寸,可洽本公司。

HGR dimensions(2-stage ratio 12~200)[mm]

.png)

| Frame size | HGR100 | HGR120 | HGR140 | HGR160 | HGR180 | HGR210 | HGR240 |

|---|---|---|---|---|---|---|---|

| W1 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 mln. | 118 | 145 | 153.5 | 153.5 | 153.5 | 176 | 176 |

| D1 (g6) | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 55 | 65 | 75 | 85 | 95 | 125 | 140 |

| D3 (H8) | 30 | 44 | 50 | 55 | 62 | 75 | 90 |

| D4 (H6) | 25 | 35 | 40 | 45 | 50 | 60 | 70 |

| D5 (H7) | 20 | 30 | 30 | 36 | 40 | 50 | 60 |

| D6 (H7) max. | 32 | 35 | 38 | 38 | 38 | 48 | 48 |

| D7 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D8 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D9 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| L1 | 290.5 | 324.3 | 363.8 | 380.3 | 377.3 | 475.3 | 501.8 |

| L2 | 28 | 34 | 40 | 42 | 45 | 48 | 56 |

| L3 | 30 | 30 | 31 | 29.8 | 29.8 | 38 | 40 |

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 2 | 3 | 4 | 2.75 | 2.75 | 3 | 3 |

| L6 | 180.5 | 198 | 223.8 | 225 | 233.5 | 292.3 | 308.8 |

| L7 | 30 | 50 | 43 | 50 | 55 | 66 | 76 |

| L8 | 45 | 70 | 63 | 75 | 85 | 100 | 112 |

| C1 | 29 | 27.2 | 37.2 | 37.2 | 37.2 | 44 | 44 |

| C2 | 24.2 | 25.3 | 26.8 | 26.8 | 26.8 | 34 | 34 |

| C3 | 13.2 | 13.8 | 14.8 | 14.8 | 14.8 | 18.5 | 18.5 |

| ※C4 min. | 31 | 32 | 35 | 35 | 35 | 42 | 42 |

| ※C5 min. | 60 | 59.2 | 72.2 | 72.2 | 72.2 | 86 | 86 |

| ※C6 min. | 129.5 | 138.7 | 158.5 | 158.5 | 158.5 | 201 | 201 |

| ※C7 min. | 181.5 | 200.2 | 227.5 | 227.5 | 227.5 | 298 | 298 |

※Actual dimensions marked above may vary from different servo motors.

We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

MACHINE TOOLS

- CNC Gantry Milling Machine / CNC Gantry Grinding Machine

- CNC Integrated Processing Machine / CNC Deephole Processing Machine

- CNC Floor Boring Machine / CNC Drilling Machine

- CNC Gantry Planing Mill / CNC Punching Machine

- CNC Heavy Duty Lathe (Horizontal or Vertical Spindle

SPECIAL PURPOSE MACHINES

- Packaging Machinery / Print Machine / Tapping machine

- Textile Machinery / Tube Bending Machine / CNC Press

- Woodworking Machine / Blow Molding Machine / Engraving Machine

- Filling Machine / Injection Molding Machine / Spring Machine

- Laser Cutting Machine / Laser Welding Machine

FACTORY AUTOMATION

- Semiconductor Machinery and Equipment / Photoelectric Panel Industry

- Gantry Loader / Automated Storage and Retrieval System

- Medical Industry / Metal Surface Treatment Equipment

High Torque Positioning System Applications

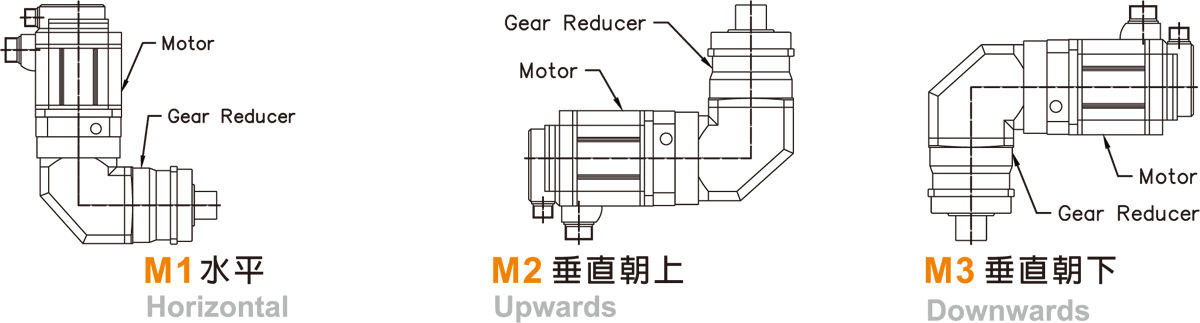

Mounting positions

Rack

Gear