運轉順暢、低噪音

- 小齒輪及齒條採螺旋系配合,並經硬化處理和精密研磨。

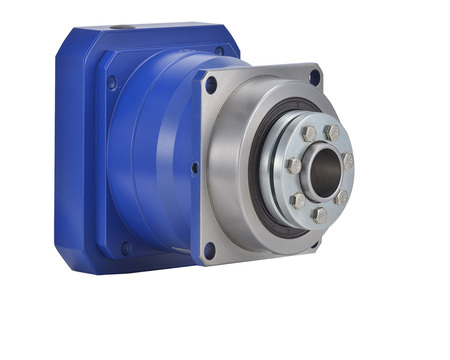

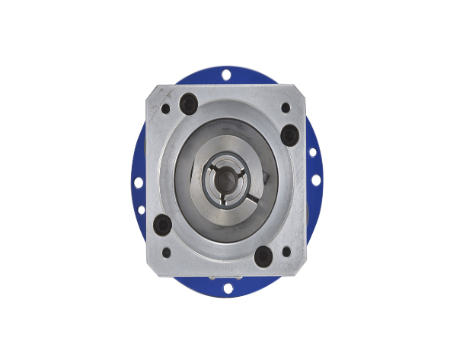

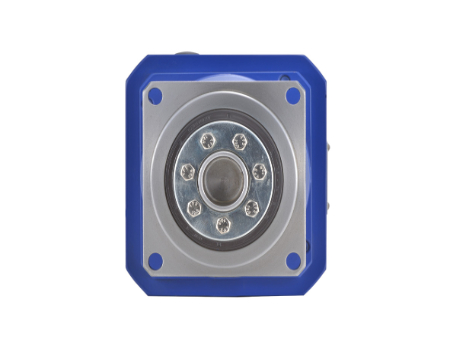

易安裝、省空間及重量

- 小齒輪與減速機中空軸以高強靭聯軸器相聯結。

減速機可承受大負荷軸/徑向推力

- 減速機輸出軸裝有一組高強度的滾錐軸承。

小齒輪與齒條可調整至最佳精度

- 透過偏心的聯接板,結構簡單,小齒輪位置易調整。

高起動性及加速時間短

- 優良的結構設計以獲得低慣性矩,啟動、停止靈敏。

高經濟效益

- 由於低慣性矩,因而能選配較小的伺服馬達,節省成本。

極佳的線性定位精度

- 小齒輪與齒條採用研磨級系列製品,齒條累積節距誤差精度為0.03/1000mm。

壽命長

- 歐規的設計結構

- 精選的西歐名牌軸承

- 德製的油封

- 齒輪經硬化處理和精密研磨

- 採高防護指數的油潤滑

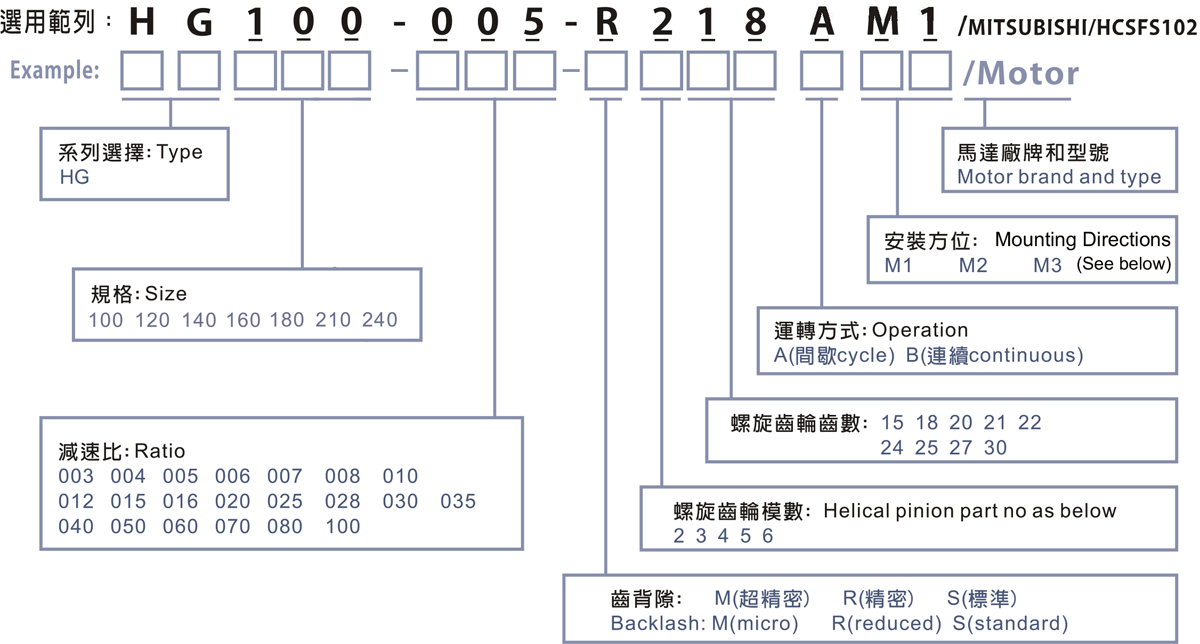

HG 技術資料 (單段) 減速比 3/4/5/6/7/8/10

| 規格 | 減速比 | HG100 | HG120 | HG140 | HG160 | HG180 | HG210 | HG240 | |

|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 3 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 4 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 5 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 6 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 7 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 8 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 10 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| 緊急停止扭矩(2) T2Not | Nm | 3 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 4 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 5 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 6 | 650 | 800 | 1120 | 1700 | 2880 | 5000 | 8950 | ||

| 7 | 625 | 780 | 1100 | 1600 | 2800 | 5500 | 8650 | ||

| 8 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 10 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 額定輸出扭矩 T2N | Nm | 3 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 4 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 5 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 6 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 7 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 8 | 120 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 10 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| 額定輸入轉速 n1N | rpm | 3 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 |

| 4 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 5 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 6 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 7 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 8 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 10 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 最大輸入轉速 n1Max | rpm | 3 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 |

| 4 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 5 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 6 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 7 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 8 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 10 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 徑向負荷力(3) Frmax | N | 3 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 4 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 5 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 6 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 7 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 8 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 10 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 軸向負荷力(3) Famax | N | 3 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 4 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 5 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 6 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 7 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 8 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 10 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 3 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 4 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 5 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 6 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 7 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 8 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 精密背隙 | arcmin | 3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 |

| 4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 5 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 6 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 7 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 8 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 標準背隙 | arcmin | 3 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 4 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 6 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 7 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 8 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 扭轉剛性 | Nm/arcmin | 3 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 4 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 6 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 7 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 8 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 10 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 滿載時使用效率 | % | 3 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 6 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 8 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 使用壽命 LH2 | h | 3 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 6 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 8 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 3 | 8 | 12 | 16 | 23 | 33 | 56 | 85 |

| 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 5 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 6 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 7 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 8 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 10 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 噪音值(4) | dB | 3 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 4 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 5 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 6 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 7 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 8 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 10 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用溫度範圍 | °C | 3 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 6 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 8 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防護等級 | 3 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 6 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 8 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 潤滑油 | 3 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 6 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 8 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 轉動慣量 | kg‧cm2 | 3 | 4.73 | 5.90 | 10.50 | 16.22 | 37.40 | 72.10 | 140.80 |

| 4 | 4.22 | 5.09 | 9.10 | 12.90 | 29.80 | 50.50 | 97.10 | ||

| 5 | 4.13 | 4.93 | 8.85 | 12.30 | 28.43 | 45.20 | 87.40 | ||

| 6 | 4.08 | 4.89 | 8.63 | 11.88 | 27.67 | 44.10 | 84.50 | ||

| 7 | 4.05 | 4.83 | 8.50 | 11.83 | 27.55 | 42.60 | 81.40 | ||

| 8 | 4.04 | 4.83 | 8.48 | 11.80 | 27.47 | 42.20 | 80.10 | ||

| 10 | 4.04 | 4.81 | 8.46 | 11.70 | 27.45 | 41.90 | 79.80 | ||

註(2)堪用期內可作1000次之動作。

註(3)輸出轉速100rpm作用於輸出軸中心。

註(4)噪音值測量於5比/輸入轉速3000rpm/距離1公尺/無負載運轉。

連續運轉將會減少減速機二分之一的使用壽命。

客戶所需之減速比,若非表內所有,可與本公司洽詢。

HG 技術資料 (雙段) 減速比12~100比

| 規格 | 減速比 | HG100 | HG120 | HG140 | HG160 | HG180 | HG210 | HG240 | |

|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 12 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 15 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 | ||

| 16 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 20 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 25 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 28 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 30 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 35 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 40 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 50 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 60 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 70 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 80 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 100 | 215 | 285 | 410 | 500 | 900 | 1500 | 2700 | ||

| 緊急停止扭矩(2) T2Not | Nm | 12 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 15 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 | ||

| 16 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 20 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 25 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 28 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 30 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 35 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 40 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 50 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 60 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 70 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 80 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 100 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 額定輸出扭矩 T2N | Nm | 12 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 15 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 | ||

| 16 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 20 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 25 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 28 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 30 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 35 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 40 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 50 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 60 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 70 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 80 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 100 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| 額定輸入轉速 n1N | rpm | 12 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 |

| 15 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 16 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 20 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 25 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 28 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 30 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 35 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 40 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 50 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 60 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 70 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 80 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 100 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 最大輸入轉速 n1Max | rpm | 12 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 |

| 15 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 16 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 20 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 25 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 28 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 30 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 35 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 40 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 50 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 60 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 70 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 80 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 100 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 徑向負荷力(3) Frmax | N | 12 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 15 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 16 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 2700 | ||

| 20 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 25 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 28 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 30 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 35 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 40 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 50 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 60 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 70 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 80 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 100 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 軸向負荷力(3) Famax | N | 12 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 15 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 16 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 20 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 25 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 28 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 30 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 35 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 40 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 50 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 60 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 70 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 80 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 100 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 12 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 15 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 16 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 20 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 25 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 28 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 30 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 35 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 40 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 50 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 60 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 70 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 80 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 精密背隙 | arcmin | 12 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 15 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 16 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 20 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 25 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 28 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 30 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 35 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 40 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 50 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 60 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 70 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 80 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 標準背隙 | arcmin | 12 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 |

| 15 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 16 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 20 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 25 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 28 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 30 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 35 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 40 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 50 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 60 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 70 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 80 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 扭轉剛性 | Nm/arcmin | 12 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 15 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 16 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 20 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 25 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 28 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 30 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 35 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 40 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 50 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 60 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 70 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 80 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 100 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 滿載時使用效率 | % | 12 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 15 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94≥ | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 30 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 60 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 80 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 使用壽命 LH2 | h | 12 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 15 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 30 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 60 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 80 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 12 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 |

| 15 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 16 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 20 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 25 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 28 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 30 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 35 | 9.2 | 15.2 | 20.3 | 23..7 | 35.5 | 59 | 87 | ||

| 40 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 50 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 60 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 70 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 80 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 100 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 噪音值(4) | dB | 12 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 15 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 16 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 20 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 25 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 28 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 30 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 35 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 40 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 50 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 60 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 70 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 80 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 100 | ≤60 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用溫度範圍 | °C | 12 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 15 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 30 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 35 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 60 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 80 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防護等級 | 12 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 15 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 30 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 40 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 60 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 80 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 潤滑油 | 12 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 15 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 30 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 60 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 80 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 轉動慣量 | kg‧cm2 | 12 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 |

| 15 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 | ||

| 16 | 4.20 | 5.09 | 9.00 | 9.30 | 9.30 | 30.00 | 31.30 | ||

| 20 | 4.20 | 5.07 | 9.00 | 9.20 | 9.30 | 30.00 | 31.00 | ||

| 25 | 4.12 | 4.91 | 8.83 | 9.00 | 9.05 | 28.70 | 30.10 | ||

| 28 | 4.20 | 5.07 | 9.00 | 9.20 | 9.20 | 29.90 | 31.00 | ||

| 30 | 4.08 | 4.90 | 8.63 | 8.65 | 8.65 | 27.70 | 29.05 | ||

| 35 | 4.12 | 4.91 | 8.82 | 8.90 | 9.03 | 28.80 | 30.08 | ||

| 40 | 4.04 | 4.80 | 8.45 | 8.50 | 8.52 | 27.70 | 28.70 | ||

| 50 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.70 | ||

| 60 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.55 | ||

| 70 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.50 | ||

| 80 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.50 | ||

| 100 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

註(2)堪用期內可作1000次之動作。

註(3)輸出轉速100rpm作用於輸出軸中心。

註(4)噪音值測量於5比/輸入轉速3000rpm/距離1公尺/無負載運轉。

連續運轉將會減少減速機二分之一的使用壽命。

客戶所需之減速比,若非表內所有,可與本公司洽詢。

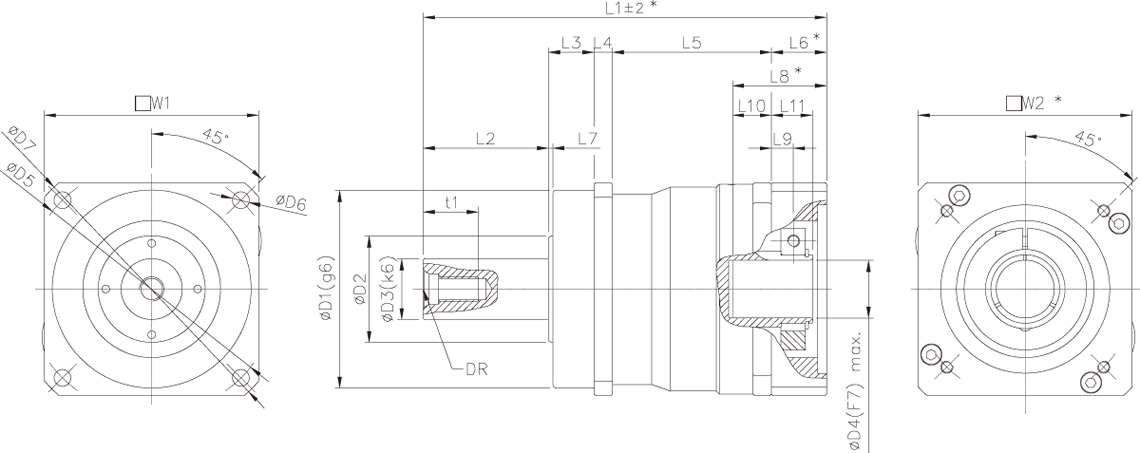

HG外觀尺寸 (單段 3 / 4 / 5 / 6 / 7 / 8 / 10 比)[mm]

| Frame size | HG100 | HG120 | HG140 | HG160 | HG180 | HG210 | HG240 |

|---|---|---|---|---|---|---|---|

| W1 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 min. | 118 | 130 | 140 | 175 | 190 | 190 | 240 |

| D1(g6) | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 60 | 65 | 75 | 85 | 95 | 125 | 140 |

| D3(h8) | 36 | 44 | 50 | 55 | 62 | 75 | 90 |

| D4(H6) | 29 | 35 | 40 | 45 | 50 | 60 | 70 |

| D5(H7) | 24 | 30 | 30 | 36 | 40 | 50 | 60 |

| D6(F7) max. | 32 | 35 | 38 | 42 | 48 | 55 | 60 |

| D7 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D8 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D9 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 183.5 | 197.5 | 221.5 | 226.5 | 260 | 292.5 | 348 |

| L2 | 36 | 35 | 40 | 42 | 45 | 48 | 56 |

| L3 | 32 | 30 | 31 | 30 | 30 | 38 | 40 |

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 97.5 | 104 | 116 | 120 | 137 | 156.5 | 174 |

| ※L6 | 28 | 28.5 | 34.5 | 34.5 | 48 | 50 | 78 |

| L7 | 4 | 3 | 4 | 3 | 3 | 3 | 3 |

| ※L8 | 52 | 52 | 60 | 60 | 82 | 82 | 110 |

| L9 | 11.5 | 12.8 | 14.3 | 14.3 | 17.8 | 18.5 | 22.5 |

| L10 | 24 | 24 | 25.5 | 25.5 | 34 | 32 | 32 |

| L11 | 22 | 24.5 | 27 | 27 | 33.5 | 34.5 | 41 |

| L12 | 30 | 42 | 43 | 50 | 55 | 66 | 76 |

| L13 | 45 | 62 | 63 | 75 | 85 | 100 | 112 |

※此記號表示之尺寸視聯結之伺服馬達不同而有所變動。

本公司的產品不斷的研究﹑發展。上表所示之尺寸力求精準,若有不符,仍以實物為準,如需確實之尺寸,可洽本公司。

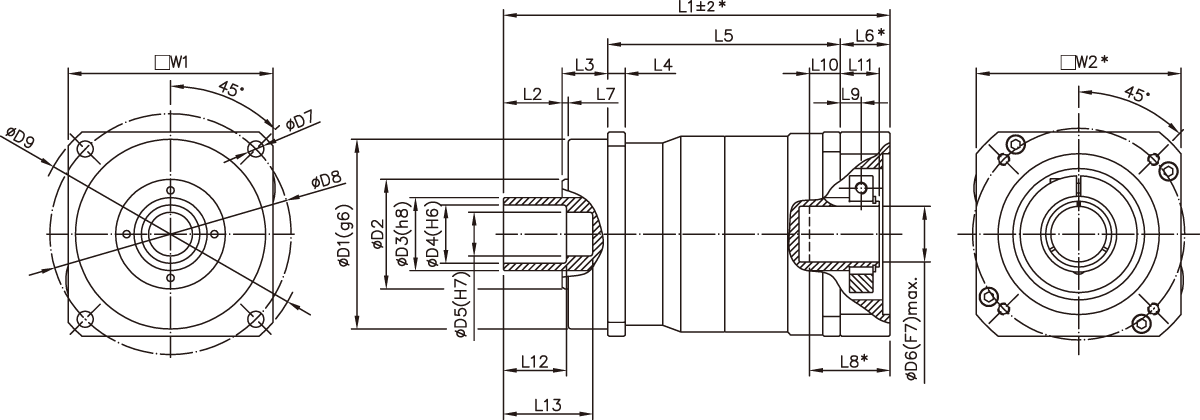

HG外觀尺寸 (雙段 12~100 比)[mm]

| 規格 | HG100 | HG120 | HG140 | HG160 | HG180 | HG210 | HG240 |

|---|---|---|---|---|---|---|---|

| W1 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 min. | 118 | 130 | 140 | 140 | 140 | 190 | 190 |

| D1(g6) | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 60 | 65 | 75 | 85 | 95 | 125 | 140 |

| D3(h8) | 36 | 44 | 50 | 55 | 62 | 75 | 90 |

| D4(H6) | 29 | 35 | 40 | 45 | 50 | 60 | 70 |

| D5(H7) | 24 | 30 | 30 | 36 | 40 | 50 | 60 |

| D6(F7) max. | 32 | 35 | 38 | 38 | 38 | 48 | 48 |

| D7 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D8 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D9 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 222 | 237.5 | 264.5 | 269.5 | 281 | 338.5 | 366 |

| L2 | 36 | 35 | 40 | 42 | 45 | 48 | 56 |

| L3 | 32 | 30 | 31 | 30 | 30 | 38 | 40 |

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 136 | 144 | 159 | 163 | 171.5 | 204.5 | 222 |

| ※L6 | 28 | 28.5 | 34.5 | 34.5 | 34.5 | 48 | 48 |

| L7 | 4 | 3 | 4 | 3 | 3 | 3 | 3 |

| ※L8 | 52 | 52 | 60 | 60 | 60 | 82 | 82 |

| L9 | 11.5 | 12.8 | 14.3 | 14.3 | 14.3 | 17.8 | 17.8 |

| L10 | L10 | 24 | 24 | 25.5 | 25.5 | 25.5 | 34 |

| L11 | 22 | 24.5 | 27 | 27 | 27 | 33.5 | 33.5 |

| L12 | 30 | 42 | 43 | 50 | 55 | 66 | 76 |

| L13 | 45 | 62 | 63 | 75 | 85 | 100 | 112 |

※此記號表示之尺寸視聯結之伺服馬達不同而有所變動。

本公司的產品不斷的研究﹑發展。上表所示之尺寸力求精準,若有不符,仍以實物為準,如需確實之尺寸,可洽本公司。

工具機業

- CNC 龍門銑床 / CNC 龍門磨床

- CNC 綜合加工機 / CNC深孔加工機

- CNC 落地搪床 / CNC鑽孔機

- CNC 龍門鉋床 / CNC 沖床

- CNC 重型臥車‧立車

產業機械

- 包裝機械 / 印刷機 / 攻牙機

- 紡織機械 / 彎管機 / CNC沖壓機

- 木工機 / 吹瓶機 / 雕刻機

- 充填機 / 射出成型機 / CNC彈簧機

- 雷射切割機 / 雷射焊接機

工廠自動化工業

- 半導體機械設備 / 光電面板業

- 機械手臂 / 自動倉儲運搬系統

- 醫療產業 / 金屬表面處理設備

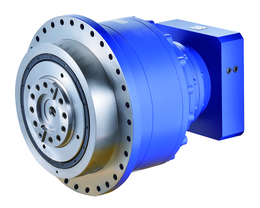

高扭力定位系統應用

搭配伺服馬達之自動化機械裝置

搭配伺服馬達之自動化機械裝置

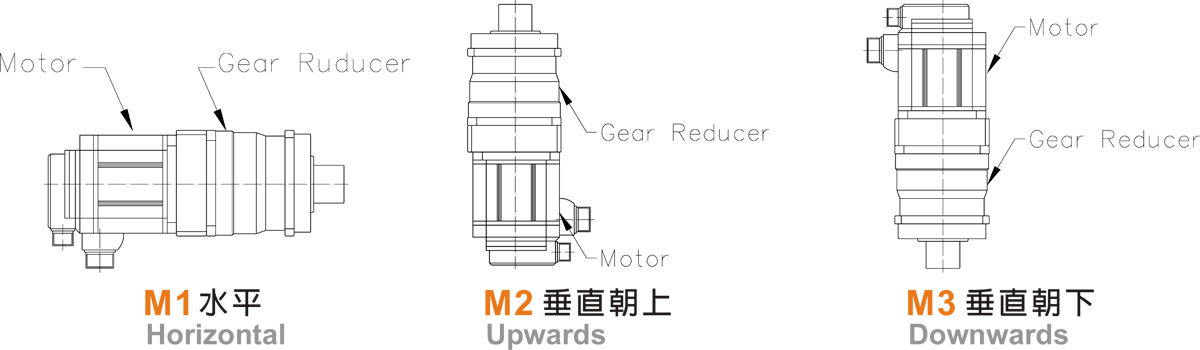

安裝方位

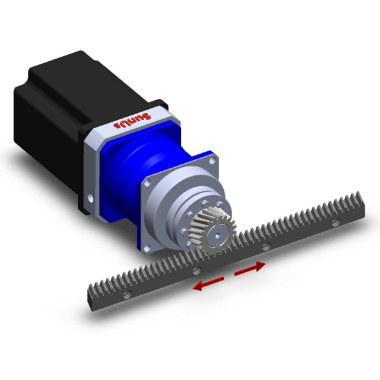

齒條傳動

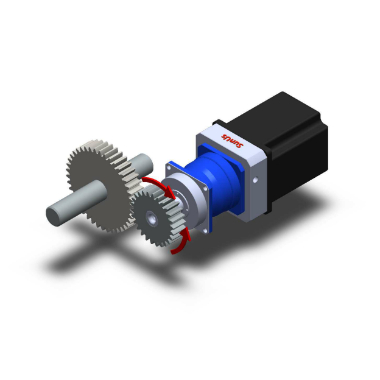

齒輪傳動