高经济效益

- 高强度较少齿数齿轮,伺服马达可选用较小规格,获得最小启动扭矩、较大刚性达到高经济效益。

运转顺畅、低噪音

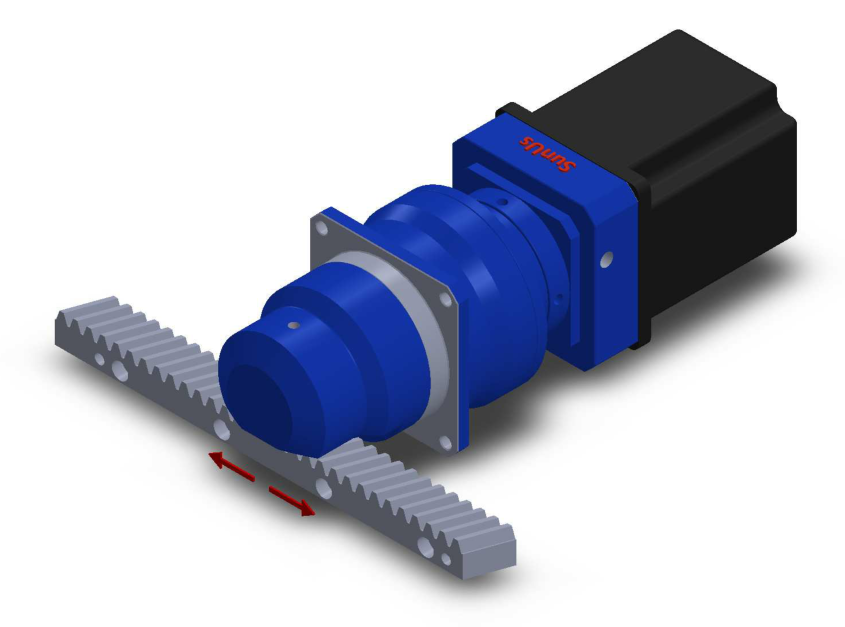

- 小齿轮及齿条采螺旋系配合,并经硬化处理和精密研磨。

可承受较大弯曲力矩

- 小齿轮辅以一滚珠轴承支撑。

减速机可承受大负荷轴/径向推力

- 减速机输出轴装有一组高强度的滚锥轴承。

小齿轮与齿条可调整至最佳精度

- 透过偏心的联接板,结构简单,小齿轮位置易调整。

反应灵敏

- 由于启动扭矩小,使系统反应灵敏。

极佳的线性定位精度

- 小齿轮与齿条采用研磨级系列制品,齿条累积节距误差精度为0.03/1000mm。

寿命长

- 欧规的设计结构

- 精选的西欧名牌轴承

- 德制的油封

- 齿轮经硬化处理和精密研磨

- 采高防护指数的油润滑

HP 技术资料 (单段) 减速比 3/4/5/6/7/8/10

| 规格 | 减速比 | HP111 | HP131 | HP151 | HP171 | HP191 | HP221 | HP251 | |

|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 3 | 208 | 338 | 450 | 750 | 1080 | 1800 | 3690 |

| 4 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 5 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 6 | 260 | 350 | 455 | 745 | 1205 | 2210 | 3870 | ||

| 7 | 247 | 320 | 450 | 720 | 1160 | 1730 | 3610 | ||

| 8 | 220 | 295 | 420 | 668 | 1055 | 1645 | 3400 | ||

| 10 | 194 | 250 | 347 | 510 | 920 | 1535 | 2760 | ||

| 紧急停止扭矩(2) T2Not | Nm | 3 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 4 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 5 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 6 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 7 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 8 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 10 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 额定输出扭矩 T2N | Nm | 3 | 138 | 200 | 322 | 515 | 900 | 1230 | 2060 |

| 4 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 5 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 6 | 158 | 215 | 325 | 470 | 865 | 1620 | 2315 | ||

| 7 | 130 | 185 | 320 | 443 | 843 | 1080 | 1750 | ||

| 8 | 125 | 180 | 300 | 420 | 775 | 1025 | 1700 | ||

| 10 | 118 | 165 | 226 | 360 | 670 | 970 | 1588 | ||

| 额定输入转速 n1N | rpm | 3 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 |

| 4 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 5 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 6 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 7 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 8 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 10 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 最大输入转速 n1Max | rpm | 3 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 |

| 4 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 5 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 6 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 7 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 8 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 10 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 径向负荷力(3) Frmax | N | 3 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 |

| 4 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 5 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 6 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 7 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 8 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 10 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 轴向负荷力3) Famax | N | 3 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 4 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 5 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 6 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 7 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 8 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 10 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 3 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 4 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 5 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 6 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 7 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 8 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 精密背隙 | arcmin | 3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 |

| 4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 5 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 6 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 7 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 8 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 标准背隙 | arcmin | 3 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 4 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 6 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 7 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 8 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 扭转刚性 | Nm/arcmin | 3 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 4 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 6 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 7 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 8 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 10 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 满载时使用效率 | % | 3 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 6 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 8 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 使用寿命 LH2 | h | 3 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 6 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 8 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 3 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 |

| 4 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 5 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 6 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 7 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 8 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 10 | 10 | 15 | 18.5 | 26 | 36 | 62 | 91 | ||

| 噪音值(4) | dB | 3 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 4 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 5 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 6 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 7 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 8 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 10 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用温度范围 | °C | 3 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 6 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 8 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防护等级 | 3 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 6 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 8 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 润滑油 | 3 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 6 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 8 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 转动惯量 | kg‧cm2 | 3 | 4.73 | 5.90 | 10.50 | 16.22 | 37.40 | 72.10 | 140.80 |

| 4 | 4.22 | 5.09 | 9.10 | 12.90 | 29.80 | 50.50 | 97.10 | ||

| 5 | 4.13 | 4.93 | 8.85 | 12.30 | 28.43 | 45.20 | 87.40 | ||

| 6 | 4.08 | 4.89 | 8.63 | 11.88 | 27.67 | 44.10 | 84.50 | ||

| 7 | 4.05 | 4.83 | 8.50 | 11.83 | 27.55 | 42.60 | 81.40 | ||

| 8 | 4.04 | 4.83 | 8.48 | 11.80 | 27.47 | 42.20 | 80.10 | ||

| 10 | 4.04 | 4.81 | 8.46 | 11.70 | 27.45 | 41.90 | 79.80 | ||

注(2)堪用期内可作1000次之动作。

注(3)输出转速100rpm作用于输出轴中心。

注(4)噪音值测量于5比/输入转速3000rpm/距离1公尺/无负载运转。

连续运转将会减少减速机二分之一的使用寿命。

客户所需之减速比,若非表内所有,可与本公司洽询。

HP 技术资料 (双段) 减速比 12~100

| 规格 | 减速比 | HP112 | HP132 | HP152 | HP172 | HP192 | HP222 | HP252 | |

|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 12 | 208 | 338 | 450 | 750 | 1080 | 1800 | 3690 |

| 15 | 208 | 228 | 450 | 750 | 1080 | 1800 | 3690 | ||

| 16 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 20 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 25 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 28 | 247 | 320 | 450 | 720 | 1160 | 1730 | 3610 | ||

| 30 | 260 | 350 | 455 | 745 | 1205 | 2210 | 3870 | ||

| 35 | 247 | 320 | 450 | 720 | 1160 | 1730 | 3610 | ||

| 40 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 50 | 280 | 362 | 530 | 850 | 1360 | 2720 | 4295 | ||

| 60 | 260 | 350 | 455 | 745 | 1205 | 2210 | 3870 | ||

| 70 | 247 | 320 | 450 | 720 | 1160 | 1730 | 3610 | ||

| 80 | 220 | 295 | 420 | 668 | 1055 | 1645 | 3400 | ||

| 100 | 194 | 250 | 347 | 510 | 920 | 1535 | 2760 | ||

| 紧急停止扭矩(2) T2Not | Nm | 12 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 15 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 | ||

| 16 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 20 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 25 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 28 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 30 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 35 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 40 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 50 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 60 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 70 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 80 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 100 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 额定输出扭矩 T2N | Nm | 12 | 138 | 200 | 322 | 515 | 900 | 1230 | 2060 |

| 15 | 138 | 200 | 322 | 515 | 900 | 1230 | 2060 | ||

| 16 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 20 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 25 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 28 | 130 | 185 | 320 | 443 | 843 | 1080 | 1750 | ||

| 30 | 158 | 215 | 325 | 470 | 865 | 1620 | 2315 | ||

| 35 | 130 | 185 | 320 | 443 | 843 | 1080 | 1750 | ||

| 40 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 50 | 192 | 250 | 355 | 580 | 1150 | 1990 | 2720 | ||

| 60 | 158 | 215 | 325 | 470 | 865 | 1620 | 2315 | ||

| 70 | 130 | 185 | 320 | 443 | 843 | 1080 | 1750 | ||

| 80 | 125 | 180 | 300 | 420 | 775 | 1025 | 1700 | ||

| 100 | 118 | 165 | 226 | 360 | 670 | 970 | 1588 | ||

| 额定输入转速 n1N | rpm | 12 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 |

| 15 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 16 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 20 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 25 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 28 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 30 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 35 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 40 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 50 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 60 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 70 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 80 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 100 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 最大输入转速 n1Max | rpm | 12 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 |

| 15 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 16 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 20 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 25 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 28 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 30 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 35 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 40 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 50 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 60 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 70 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 80 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 100 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 径向负荷力(3) Frmax | N | 12 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 |

| 15 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 16 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 20 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 25 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 28 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 30 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 35 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 40 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 50 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 60 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 70 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 80 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 100 | 9600 | 12000 | 14400 | 18400 | 22400 | 28800 | 43200 | ||

| 轴向负荷力3) Famax | N | 12 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 15 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 16 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 20 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 25 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 28 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 30 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 35 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 40 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 50 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 60 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 70 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 80 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 100 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 12 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 15 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 16 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 20 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 25 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 28 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 30 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 35 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 40 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 50 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 60 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 70 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 80 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 精密背隙 | arcmin | 12 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 15 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 16 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 20 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 25 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 28 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 30 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 35 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 40 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 50 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 60 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 70 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 80 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 标准背隙 | arcmin | 12 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 |

| 15 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 16 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 20 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 25 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 28 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 30 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 35 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 40 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 50 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 60 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 70 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 80 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 扭转刚性 | Nm/arcmin | 12 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 15 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 16 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 20 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 25 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 28 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 30 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 35 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 40 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 50 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 60 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 70 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 80 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 100 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 满载时使用效率 | % | 12 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 15 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 30 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 60 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 80 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 使用寿命 LH2 | h | 12 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 15 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 30 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 60 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 80 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 12 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 |

| 15 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 16 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 20 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 25 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 28 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 30 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 35 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 40 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 50 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 60 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 70 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 80 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 100 | 11.2 | 18.2 | 22.8 | 26.7 | 38.5 | 65 | 93 | ||

| 噪音值(4) | dB | 12 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 15 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 16 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 20 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 25 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 28 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 30 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 35 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 40 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 50 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 60 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 70 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 80 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 100 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用温度范围 | °C | 12 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 15 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 30 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 60 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 80 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防护等级 | 12 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 15 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 30 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 40 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 60 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 80 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 润滑油 | 12 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 15 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 30 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 60 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 80 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 转动惯量 | kg‧cm2 | 12 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 |

| 15 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 | ||

| 16 | 4.20 | 5.09 | 9.00 | 9.30 | 9.30 | 30.00 | 31.30 | ||

| 20 | 4.20 | 5.07 | 9.00 | 9.20 | 9.30 | 30.00 | 31.00 | ||

| 25 | 4.12 | 4.91 | 8.83 | 9.00 | 9.05 | 28.70 | 30.10 | ||

| 28 | 4.20 | 5.07 | 9.00 | 9.20 | 9.20 | 29.90 | 31.00 | ||

| 30 | 4.08 | 4.90 | 8.63 | 8.65 | 8.65 | 27.70 | 29.05 | ||

| 35 | 4.12 | 4.91 | 8.82 | 8.90 | 9.03 | 28.80 | 30.08 | ||

| 40 | 4.04 | 4.80 | 8.45 | 8.50 | 8.52 | 27.70 | 28.70 | ||

| 50 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.70 | ||

| 60 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.55 | ||

| 70 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.50 | ||

| 80 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

| 100 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

注(2)堪用期内可作1000次之动作。

注(3)输出转速100rpm作用于输出轴中心。

注(4)噪音值测量于5比/输入转速3000rpm/距离1公尺/无负载运转。

连续运转将会减少减速机二分之一的使用寿命。

客户所需之减速比,若非表内所有,可与本公司洽询。

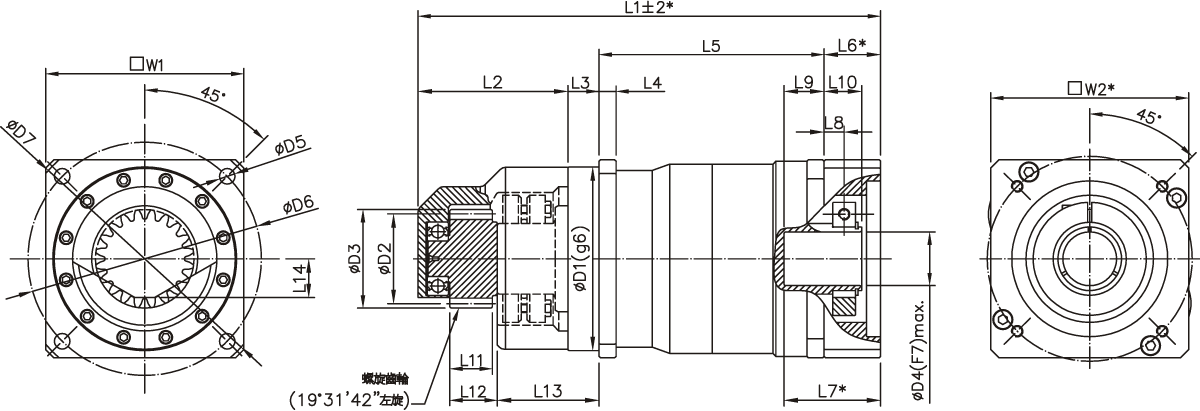

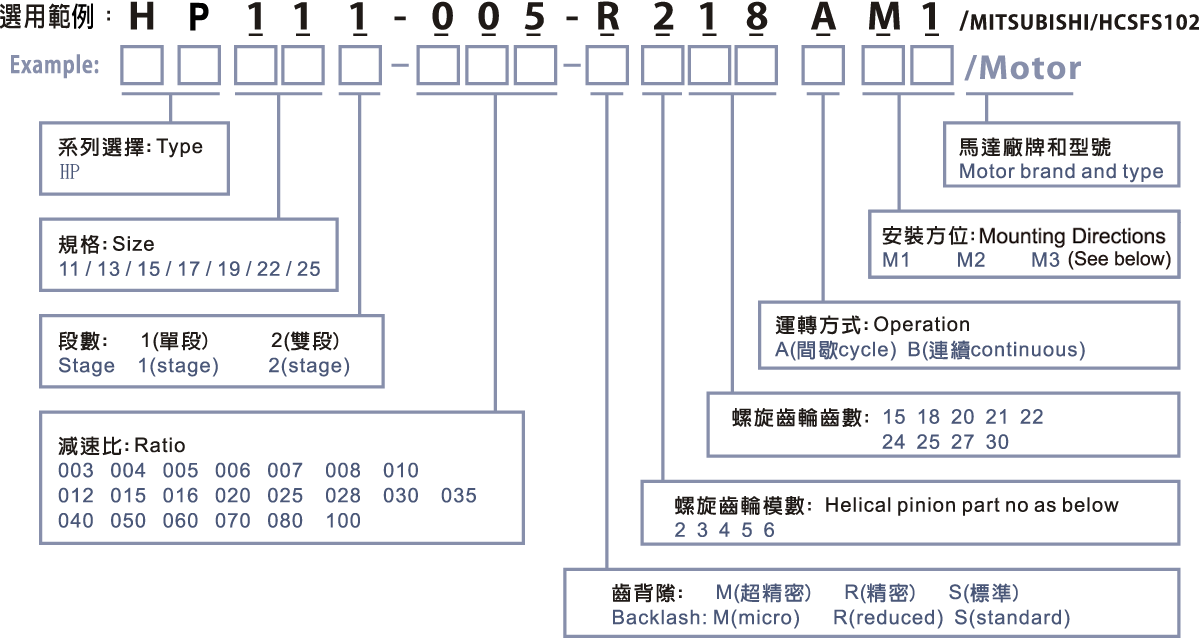

HP dimensions (1-stage ratio 3 / 4 / 5 / 6 / 7 / 8 / 10)[mm]

.png)

| 尺寸 | HP112 | HP132 | HP152 | HP172 | HP192 | HP222 | HP252 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 规格 | |||||||||||||||||||||

| 模数 m | 2 | 2 | 3 | 4 | 4 | 5 | 6 | ||||||||||||||

| 齿数 Z | 18 | 21 | 24 | 24 | 27 | 30 | 20 | 22 | 25 | 15 | 18 | 21 | 15 | 18 | 21 | 15 | 18 | 21 | 15 | 18 | 20 |

| 移位系数 | - | - | - | - | - | - | - | - | - | 0.355 | - | - | 0.355 | - | - | 0.3723 | - | - | 0.3756 | - | - |

| W1 | 100 | 120 | 140 | 160 | 182 | 210 | 240 | ||||||||||||||

| ※W2 min. | 118 | 130 | 140 | 175 | 190 | 190 | 240 | ||||||||||||||

| D1(g6) | 90 | 110 | 130 | 145 | 160 | 180 | 200 | ||||||||||||||

| D2 | 38.2 | 44.56 | 50.93 | 50.93 | 57.29 | 63.66 | 63.66 | 70.03 | 79.58 | 63.66 | 76.39 | 89.13 | 63.66 | 76.39 | 89.13 | 79.58 | 95.49 | 111.41 | 95.49 | 114.59 | 127.32 |

| D3 | 42.2 | 48.56 | 54.93 | 54.93 | 61.29 | 67.66 | 69.66 | 76.03 | 85.58 | 74.5 | 84.39 | 97.13 | 74.5 | 84.39 | 97.13 | 93.3 | 105.49 | 121.41 | 112 | 126.59 | 139.32 |

| D4(F7) | 32 | 35 | 38 | 42 | 48 | 55 | 60 | ||||||||||||||

| D5 | 9 | 9 | 11 | 13 | 13 | 17 | 17 | ||||||||||||||

| D6 | 120 | 130 | 165 | 190 | 215 | 250 | 290 | ||||||||||||||

| D7 | 135 | 155 | 185 | 215 | 240 | 279 | 320 | ||||||||||||||

| ※L1 | 225.5 | 243 | 277.5 | 291 | 325.5 | 372.5 | 439 | ||||||||||||||

| L2 | 75 | 87.5 | 105 | 114.5 | 118.5 | 136 | 156 | ||||||||||||||

| L3 | 25 | 23 | 22 | 22 | 22 | 30 | 31 | ||||||||||||||

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 | ||||||||||||||

| L5 | 97.5 | 104 | 116 | 120 | 137 | 156.5 | 174 | ||||||||||||||

| ※L6 | 28 | 28.5 | 34.5 | 34.5 | 48 | 50 | 78 | ||||||||||||||

| ※L7 | 52 | 52 | 60 | 60 | 82 | 82 | 110 | ||||||||||||||

| L8 | 11.5 | 12.8 | 14.3 | 14.3 | 17.8 | 18.5 | 22.5 | ||||||||||||||

| L9 | 24 | 24 | 25.5 | 25.5 | 34 | 32 | 32 | ||||||||||||||

| L10 | 22 | 24.5 | 27 | 27 | 33.5 | 34.5 | 41 | ||||||||||||||

| L11 | 25 | 25 | 30 | 40 | 40 | 50 | 60 | ||||||||||||||

| L12 | 28.5 | 28.5 | 33.5 | 43.5 | 45.5 | 55.5 | 68 | ||||||||||||||

| L13 | 58 | 64.75 | 72 | 71.75 | 72.75 | 86 | 91.5 | ||||||||||||||

| L14 | 16.2 | 22.5 | 27.5 | 27.5 | 27.5 | 34.5 | 41 | ||||||||||||||

※此记号表示之尺寸视联结之伺服马达不同而有所变动。

本公司的产品不断的研究﹑发展。上表所示之尺寸力求精准,若有不符,仍以实物为准,如需确实之尺寸,可洽本公司。

HP 外观尺寸 (双段 12~100比)[mm]

| 规格 | HP112 | HP132 | HP152 | HP172 | HP192 | HP222 | HP252 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 模数 | 2 | 2 | 3 | 4 | 4 | 5 | 6 | ||||||||||||||

| 齿数 Z | 18 | 21 | 24 | 24 | 27 | 30 | 20 | 22 | 25 | 15 | 18 | 21 | 15 | 18 | 21 | 15 | 18 | 21 | 15 | 18 | 20 |

| 移位系数 | - | - | - | - | - | - | - | - | - | 0.355 | - | - | 0.355 | - | - | 0.3723 | - | - | 0.3756 | - | - |

| W1 | 100 | 120 | 140 | 160 | 182 | 210 | 240 | ||||||||||||||

| ※W2 min. | 118 | 130 | 140 | 140 | 140 | 190 | 190 | ||||||||||||||

| D1(g6) | 90 | 110 | 130 | 145 | 160 | 180 | 200 | ||||||||||||||

| D2 | 38.2 | 44.56 | 50.93 | 50.93 | 57.29 | 63.66 | 63.66 | 70.03 | 79.58 | 63.66 | 76.39 | 89.13 | 63.66 | 76.39 | 89.13 | 79.58 | 95.49 | 111.41 | 95.49 | 114.59 | 127.32 |

| D3 | 42.2 | 48.56 | 54.93 | 54.93 | 61.29 | 67.66 | 69.66 | 76.03 | 85.58 | 74.5 | 84.39 | 97.13 | 74.5 | 84.39 | 97.13 | 93.3 | 105.49 | 121.41 | 112 | 126.59 | 139.32 |

| D4(F7) | 32 | 35 | 38 | 38 | 38 | 48 | 48 | ||||||||||||||

| D5 | 9 | 9 | 11 | 13 | 13 | 17 | 17 | ||||||||||||||

| D6 | 120 | 130 | 165 | 190 | 215 | 250 | 290 | ||||||||||||||

| D7 | 135 | 155 | 185 | 215 | 240 | 279 | 320 | ||||||||||||||

| ※L1 | 264 | 283 | 320.5 | 334 | 360 | 420.5 | 487 | ||||||||||||||

| L2 | 75 | 87.5 | 105 | 114.5 | 118.5 | 136 | 156 | ||||||||||||||

| L3 | 25 | 23 | 22 | 22 | 22 | 30 | 31 | ||||||||||||||

| L4 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 | ||||||||||||||

| L5 | 136 | 144 | 159 | 163 | 171.5 | 204.5 | 222 | ||||||||||||||

| ※L6 | 28 | 28.5 | 34.5 | 34.5 | 48 | 50 | 78 | ||||||||||||||

| ※L7 | 52 | 52 | 60 | 60 | 82 | 82 | 82 | ||||||||||||||

| L8 | 11.5 | 12.8 | 14.3 | 14.3 | 14.3 | 17.8 | 17.8 | ||||||||||||||

| L9 | 24 | 24 | 25.5 | 25.5 | 25.5 | 34 | 34 | ||||||||||||||

| L10 | 22 | 24.5 | 27 | 27 | 27 | 33.5 | 33.5 | ||||||||||||||

| L11 | 25 | 25 | 30 | 40 | 40 | 50 | 60 | ||||||||||||||

| L12 | 28.5 | 28.5 | 33.5 | 43.5 | 45.5 | 55.5 | 68 | ||||||||||||||

| L13 | 58 | 64.75 | 72 | 71.75 | 72.75 | 86 | 91.5 | ||||||||||||||

| L14 | 16.2 | 22.5 | 27.5 | 27.5 | 27.5 | 34.5 | 41 | ||||||||||||||

※此记号表示之尺寸视联结之伺服马达不同而有所变动。

本公司的产品不断的研究﹑发展。上表所示之尺寸力求精准,若有不符,仍以实物为准,如需确实之尺寸,可洽本公司。

工具机业

- CNC 龙门铣床 / CNC 龙门磨床

- CNC 综合加工机 / CNC深孔加工机

- CNC 落地搪床 / CNC钻孔机

- CNC 龙门刨床 / CNC 冲床

- CNC 重型卧车‧立车

产业机械

- 包装机械 / 印刷机 / 攻牙机

- 纺织机械 / 弯管机 / CNC冲压机

- 木工机 / 吹瓶机 / 雕刻机

- 充填机 / 射出成型机 / CNC弹簧机

- 雷射切割机 / 雷射焊接机

工厂自动化工业

- 半导体机械设备 / 光电面板业

- 机械手臂 / 自动仓储运搬系统

- 医疗产业 / 金属表面处理设备

高扭力定位系统应用

搭配伺服马达之自动化机械装置

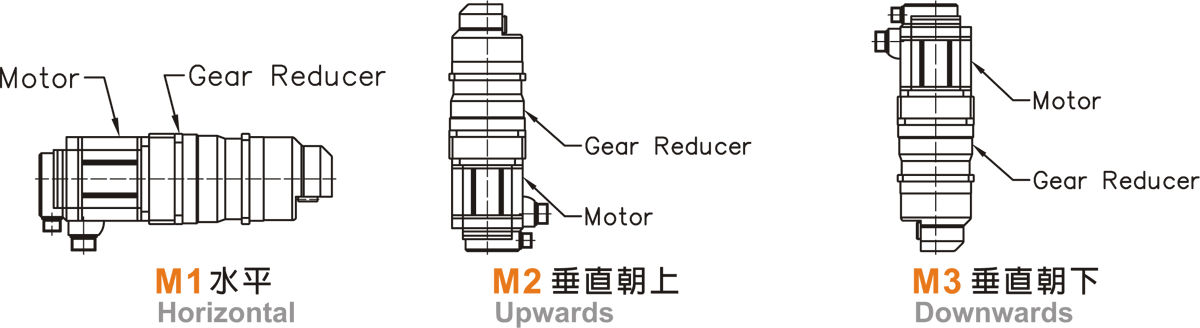

安装方位

齿条传动