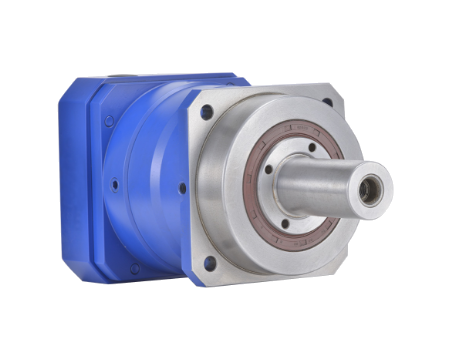

高定位精度

- 精密齿轮研磨,齿面光滑,齿形精准。

- 齿轮箱和内环齿采整体结构设计,特殊合金钢材,稳定性高。

易安装

- 减速机联接板及输入轴孔尺寸采弹性设计,能与各厂牌的伺服马逹相结合。

高扭力

- 高品质滚锥轴承,输出轴能承受更大的轴向和径向的负荷,超大扭力,应用范围广。

高起动性

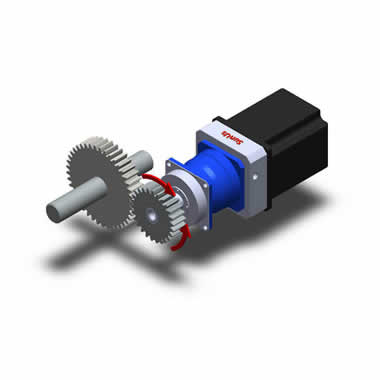

- 行星式结构平衡特性及高精度,低惯性矩,配合伺服马达具有高起动特性。

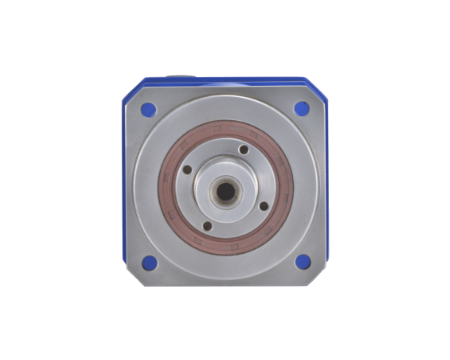

低齿背隙

- 精密加工和严格品质管制:

超精密齿背隙在一段为1弧分;两段为3弧分。

精密齿背隙在一段为2~3弧分;两段为4~5弧分。

标准齿背隙在一段为4~5弧分;两段为6~7弧分。

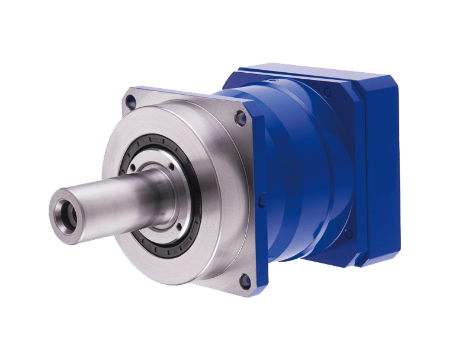

长寿命,免保养

- 采用高级镍铬钼合金钢材,经深层的渗碳硬化处理后,再经精密齿面研磨,使得齿轮刚性大,且齿面光滑耐磨性佳,可延长使用寿命。

- 采用德制优质人工合成润滑油,流动性佳,富含极压抗压剂,齿箱内各零件间充分得到润滑及保护,可免换机油。

- 采用特制高品质、耐热、耐磨不易变质之油封,使得密封性佳。

低噪音

- 采用精密研磨齿轮,齿面平滑,精度高,齿轮运转平顺而噪音小。

- 采用德制精选人工合成润滑油,非一般减速机使用油脂润滑,流动性佳,齿轮能在充分油膜保护下运转,降低噪音。

PG技术资料 (单段) 减速比 3/4/5/6/7/8/10

| 规格 | 减速比 | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 3 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 4 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 5 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 6 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 7 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 8 | 33 | 91 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 10 | 32 | 77 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| 紧急停止扭矩(2) T2Not | Nm | 3 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 4 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 5 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 6 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 7 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 8 | 77 | 250 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 10 | 75 | 200 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 额定输出扭矩 T2N | Nm | 3 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 4 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 5 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 6 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 7 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 8 | 18 | 64 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 10 | 15 | 43 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| 额定输入转速 n1N | rpm | 3 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 |

| 4 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 5 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 6 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 7 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 8 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 10 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 最大输入转速 n1Max | rpm | 3 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 |

| 4 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 5 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 6 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 7 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 8 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 10 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 径向负荷力(3) Frmax | N | 3 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 4 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 5 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 6 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 7 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 8 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 10 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 轴向负荷力3) Famax | N | 3 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 4 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 5 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 6 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 7 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 8 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 10 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 3 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 4 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 5 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 6 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 7 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 8 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 10 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 精密背隙 | arcmin | 3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 |

| 4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 5 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 6 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 7 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 8 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 标准背隙 | arcmin | 3 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 4 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 6 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 7 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 8 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 扭转刚性 | Nm/arcmin | 3 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 4 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 5 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 6 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 7 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 8 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 10 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 满载时使用效率 | % | 3 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 6 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 8 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 使用寿命 LH2 | h | 3 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 6 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 8 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 3 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 |

| 4 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 5 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 6 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 7 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 8 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 10 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 噪音值(4) | dB | 3 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 4 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 5 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 6 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 7 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 8 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 10 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用温度范围 | °C | 3 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 6 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 8 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防护等级 | 3 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 6 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 8 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 润滑油 | 3 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 6 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 8 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 转动惯量 | kg‧cm2 | 3 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 16.22 | 37.40 | 72.10 | 140.80 |

| 4 | 0.30 | 0.60 | 4.22 | 5.09 | 9.10 | 12.90 | 29.80 | 50.50 | 97.10 | ||

| 5 | 0.29 | 0.59 | 4.13 | 4.93 | 8.85 | 12.30 | 28.43 | 45.20 | 87.40 | ||

| 6 | 0.29 | 0.58 | 4.08 | 4.89 | 8.63 | 11.88 | 27.67 | 44.10 | 84.50 | ||

| 7 | 0.28 | 0.58 | 4.05 | 4.83 | 8.50 | 11.83 | 27.55 | 42.60 | 81.40 | ||

| 8 | 0.28 | 0.57 | 4.04 | 4.83 | 8.48 | 11.80 | 27.47 | 42.20 | 80.10 | ||

| 10 | 0.27 | 0.57 | 4.04 | 4.81 | 8.46 | 11.70 | 27.45 | 41.90 | 79.80 | ||

注(1)本表适用于启动频率1000次/小时以内,若超出时,请与本公司洽询。

注(2)堪用期内可作1000次之动作。

注(3)输出转速100rpm作用于输出轴中心。

注(4)噪音值测量于5比/输入转速3000rpm/距离1公尺/无负载运转。

连续运转将会减少减速机二分之一的使用寿命。

客户所需之减速比,若非表内所有,可与本公司洽询。

PG技术资料 (双段) 减速比 12~100

| 规格 | 减速比 | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 最大加速扭矩 (1) T2B | Nm | 12 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 15 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 | ||

| 16 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 20 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 25 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 28 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 30 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 35 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 40 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 50 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 60 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 70 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 80 | 33 | 91 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 100 | 32 | 77 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| 紧急停止扭矩(2) T2Not | Nm | 12 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 15 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 | ||

| 16 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 20 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 25 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 28 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 30 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 35 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 40 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 50 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 60 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 70 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 80 | 77 | 250 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 100 | 75 | 200 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| 额定输出扭矩 T2N | Nm | 12 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 15 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 | ||

| 16 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 20 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 25 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 28 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 30 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 35 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 40 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 50 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 60 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 70 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 80 | 18 | 64 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 100 | 15 | 43 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| 额定输入转速 n1N | rpm | 12 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 |

| 15 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 16 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 20 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 25 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 28 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 30 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 35 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 40 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 50 | 4800 | 3900 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 60 | 4800 | 3900 | 3600 | 3300 | 3200 | 3100 | 3000 | 1580 | 2200 | ||

| 70 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 80 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 100 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 最大输入转速 n1Max | rpm | 12 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 |

| 15 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 16 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 20 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 25 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 28 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 30 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 35 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 40 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 50 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 60 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 70 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 80 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 100 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 径向负荷力(3) Frmax | N | 12 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 15 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 16 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 20 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 25 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 28 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 30 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 35 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 40 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 50 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 60 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 70 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 80 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 100 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 轴向负荷力3) Famax | N | 12 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 15 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 16 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 20 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 25 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 28 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 30 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 35 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 40 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 50 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 60 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 70 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 80 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 100 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 超精密背隙 | arcmin | 12 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 15 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 16 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 20 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 25 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 28 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 30 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 35 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 40 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 50 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 60 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 70 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 80 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 100 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 精密背隙 | arcmin | 12 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 15 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 16 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 20 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 35 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 40 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 50 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 60 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 70 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 80 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 标准背隙 | arcmin | 12 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 |

| 15 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 16 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 20 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 25 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 28 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 30 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 35 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 40 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 50 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 60 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 70 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 80 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 扭转刚性 | Nm/arcmin | 12 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 15 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 16 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 20 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 25 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 28 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 30 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 35 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 40 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 50 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 60 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 70 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 80 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 100 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 满载时使用效率 | % | 12 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 15 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 30 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 60 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 80 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 使用寿命 LH2 | h | 12 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 15 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 30 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 60 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 80 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 重量 | kg | 12 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 |

| 15 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 16 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 20 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 25 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 28 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 30 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 35 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 40 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 50 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 60 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 70 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 80 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 100 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 噪音值(4) | dB | 12 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 15 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 16 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 20 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 25 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 28 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 30 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 35 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 40 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 50 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 60 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 70 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 80 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 100 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 使用温度范围 | °C | 12 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 15 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 30 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 35 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 60 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 80 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 防护等级 | 12 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 15 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 30 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 60 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 80 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 润滑油 | 12 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 15 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 30 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 60 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 80 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 转动惯量 | kg‧cm2 | 12 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 |

| 15 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 | ||

| 16 | 0.30 | 0.60 | 4.20 | 5.09 | 9.00 | 9.30 | 9.30 | 30.00 | 31.00 | ||

| 20 | 0.30 | 0.60 | 4.20 | 5.07 | 9.00 | 9.20 | 9.30 | 30.00 | 31.00 | ||

| 25 | 0.29 | 0.59 | 4.12 | 4.91 | 8.83 | 9.00 | 9.05 | 28.70 | 30.10 | ||

| 28 | 0.30 | 0.59 | 4.20 | 5.07 | 9.00 | 9.20 | 9.20 | 29.90 | 31.00 | ||

| 30 | - | 0.58 | 4.08 | 4.90 | 8.63 | 8.65 | 9.65 | 27.70 | 29.05 | ||

| 35 | 0.30 | 0.58 | 4.12 | 4.91 | 8.82 | 8.90 | 9.03 | 28.80 | 30.08 | ||

| 40 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.50 | 8.52 | 27.70 | 28.70 | ||

| 50 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.70 | ||

| 60 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.55 | ||

| 70 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.50 | ||

| 80 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

| 100 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

注(1)本表适用于启动频率1000次/小时以内,若超出时,请与本公司洽询。

注(2)堪用期内可作1000次之动作。

注(3)输出转速100rpm作用于输出轴中心。

注(4)噪音值测量于5比/输入转速3000rpm/距离1公尺/无负载运转。

连续运转将会减少减速机二分之一的使用寿命。

客户所需之减速比,若非表内所有,可与本公司洽询。

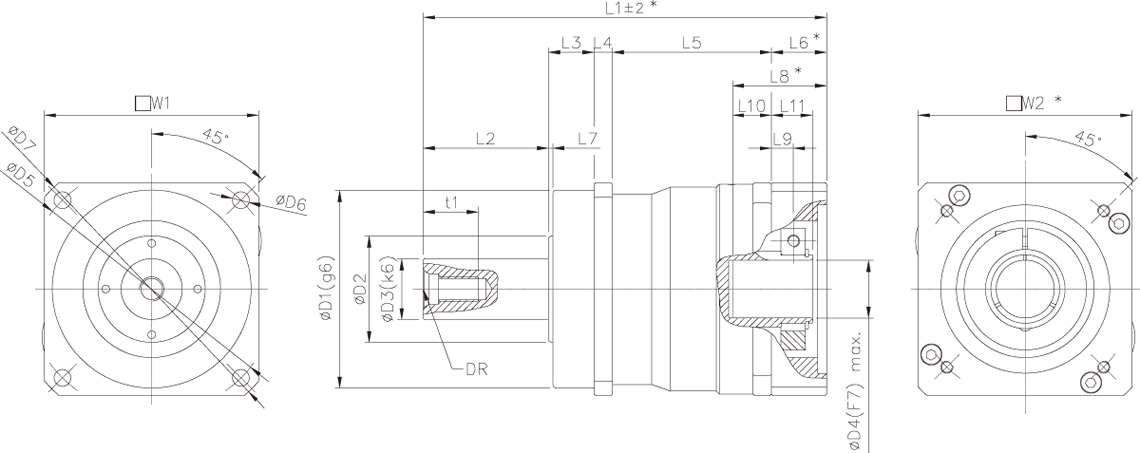

PG外观尺寸 (单段 3 / 4 / 5 / 6 / 7 / 8 / 10 比)[mm]

| 規格 | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 |

|---|---|---|---|---|---|---|---|---|---|

| W1 | 62 | 80 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 mln. | 75 | 88 | 118 | 130 | 140 | 175 | 190 | 190 | 240 |

| DR | M5 | M8 | M12 | M12 | M16 | M16 | M20 | M20 | M20 |

| t1 | 12.5 | 19 | 28 | 28 | 36 | 36 | 42 | 42 | 42 |

| D1 (g6) | 60 | 70 | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 30 | 40 | 55 | 60 | 70 | 85 | 95 | 125 | 140 |

| D3 (k6) | 16 | 22 | 32 | 35 | 40 | 50 | 55 | 75 | 85 |

| D4 (F7) max. | 14 | 19 | 32 | 35 | 38 | 42 | 48 | 55 | 60 |

| D5 | 68 | 85 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D6 | 5.5 | 6.6 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D7 | 79 | 103 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 135.5 | 161 | 213.5 | 232.5 | 262.5 | 266.5 | 297 | 349.5 | 422 |

| L2 | 28 | 36 | 58 | 70 | 82 | 82 | 82 | 105 | 130 |

| L3 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 38 | 40 |

| L4 | 6 | 7 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 60.5 | 73 | 87.5 | 93 | 104 | 106.5 | 122 | 139.5 | 154 |

| ※L6 min. | 22.5 | 25 | 28 | 28.5 | 34.5 | 34.5 | 48 | 50 | 78 |

| L7 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| ※L8 min. | 33 | 40 | 52 | 52 | 60 | 60 | 82 | 82 | 110 |

| L9 | 10 | 11.5 | 11.5 | 12.8 | 14.3 | 14.3 | 17.8 | 18.5 | 22.5 |

| L10 | 12 | 15 | 24 | 24 | 25.5 | 25.5 | 34 | 32 | 32 |

| L11 | 18 | 20 | 22 | 24.5 | 27 | 27 | 33.5 | 34.5 | 41 |

※此记号表示之尺寸视联结之伺服马达不同而有所变动。

本公司的产品不断的研究﹑发展。上表所示之尺寸力求精准,若有不符,仍以实物为准,如需确实之尺寸,可洽本公司。

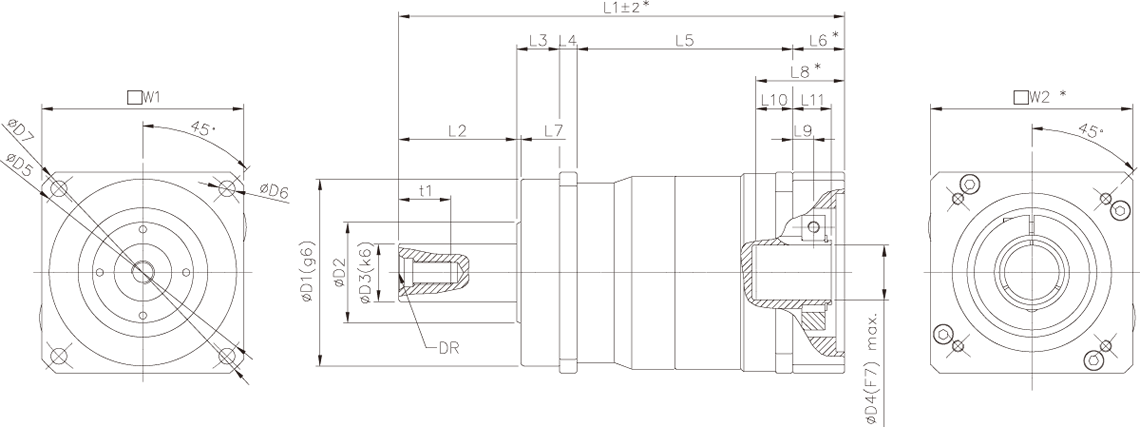

PG外观尺寸 (双段 12 ~ 100 比)[mm]

| 规格 | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 |

|---|---|---|---|---|---|---|---|---|---|

| W1 | 62 | 80 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 mln. | 72 | 88 | 118 | 130 | 140 | 140 | 140 | 190 | 190 |

| DR | M5 | M8 | M12 | M12 | M16 | M16 | M20 | M20 | M20 |

| t1 | 12.5 | 19 | 28 | 28 | 36 | 36 | 42 | 42 | 42 |

| D1 (g6) | 60 | 70 | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 30 | 40 | 55 | 60 | 70 | 85 | 95 | 125 | 140 |

| D3 (k6) | 16 | 22 | 32 | 35 | 40 | 50 | 55 | 75 | 85 |

| D4 (F7) max. | 14 | 19 | 32 | 35 | 38 | 38 | 38 | 48 | 48 |

| D5 | 68 | 85 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D6 | 5.5 | 6.6 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D7 | 79 | 103 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 157.5 | 193 | 252 | 272.5 | 305.5 | 309.5 | 318 | 395.5 | 440 |

| L2 | 28 | 36 | 58 | 70 | 82 | 82 | 82 | 105 | 130 |

| L3 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 38 | 40 |

| L4 | 6 | 7 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 82.5 | 105 | 126 | 133 | 147 | 149.5 | 156.5 | 187.5 | 202 |

| ※L6 min. | 22.5 | 25 | 28 | 28.5 | 34.5 | 34.5 | 34.5 | 48 | 48 |

| L7 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| ※L8 min. | 33 | 40 | 52 | 52 | 60 | 60 | 60 | 82 | 82 |

| L9 | 10 | 11.5 | 11.5 | 12.8 | 14.3 | 14.3 | 14.3 | 17.8 | 17.8 |

| L10 | 12 | 15 | 24 | 24 | 25.5 | 25.5 | 25.5 | 34 | 34 |

| L11 | 18 | 20 | 22 | 24.5 | 27 | 27 | 27 | 33.5 | 33.5 |

※此记号表示之尺寸视联结之伺服马达不同而有所变动。

本公司的产品不断的研究﹑发展。上表所示之尺寸力求精准,若有不符,仍以实物为准,如需确实之尺寸,可洽本公司

工具机业

- CNC 龙门铣床 / CNC 龙门磨床

- CNC 综合加工机 / CNC深孔加工机

- CNC 落地搪床 / CNC钻孔机

- CNC 龙门刨床 / CNC 冲床

- CNC 重型卧车‧立车

产业机械

- 包装机械 / 印刷机 / 攻牙机

- 纺织机械 / 弯管机 / CNC冲压机

- 木工机 / 吹瓶机 / 雕刻机

- 充填机 / 射出成型机 / CNC弹簧机

- 雷射切割机 / 雷射焊接机

工厂自动化工业

- 半导体机械设备 / 光电面板业

- 机械手臂 / 自动仓储运搬系统

- 医疗产业 / 金属表面处理设备

高扭力定位系统应用

搭配伺服马达之自动化机械装置

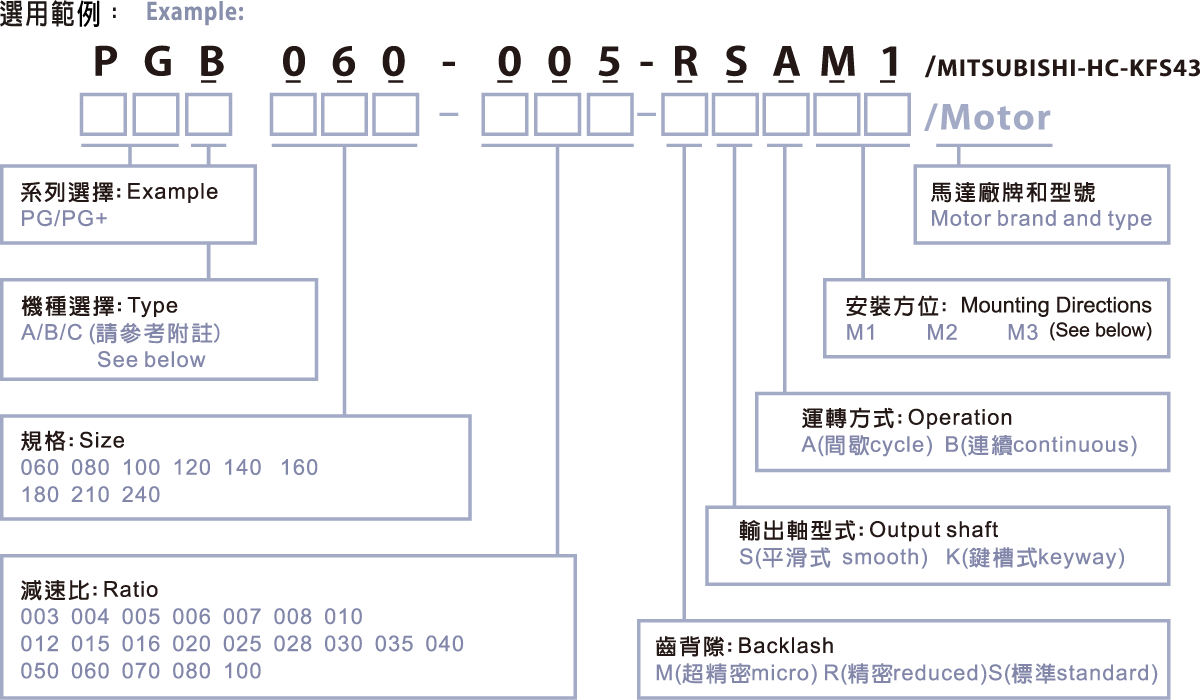

機種選擇

A : 適用於軍工事業﹑航太工業﹑及半導體產業,每日連續運作超過10小時,及需求大扭力,高精度之工作母機。

B : 適用於工廠自動化相關產業﹑一般產業機械﹑機械臂,及工作母機。

C : 適用於運轉周期為非連續性,且使用頻率較小之自動化及工作母機。

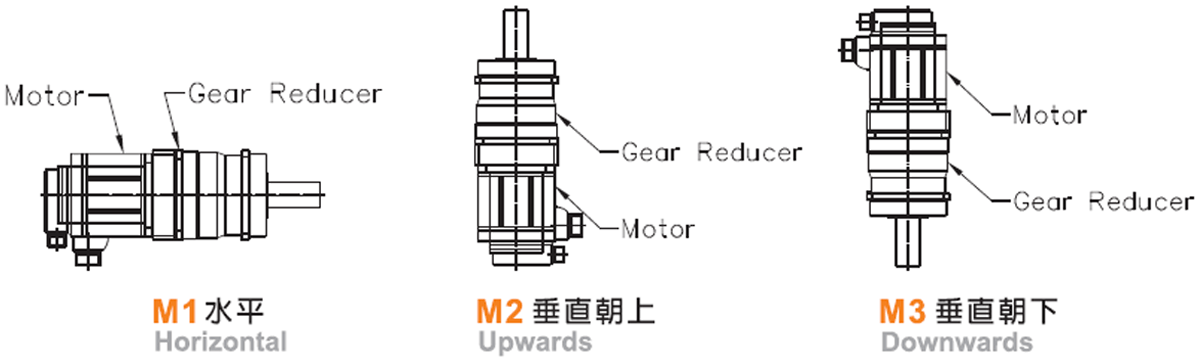

安裝方位

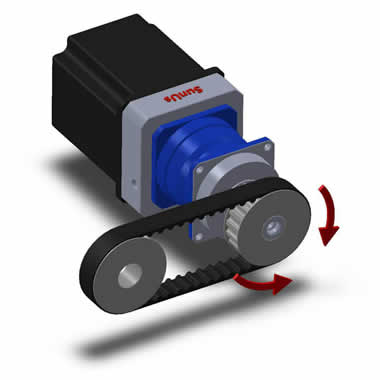

皮带传动

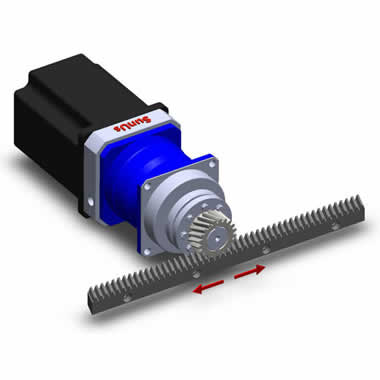

齿条传动

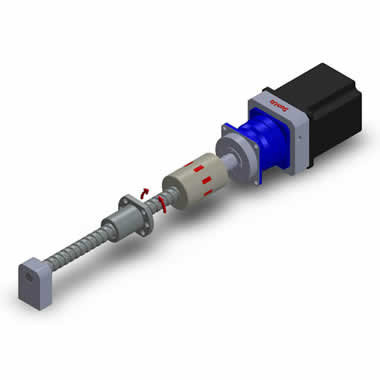

螺杆传动