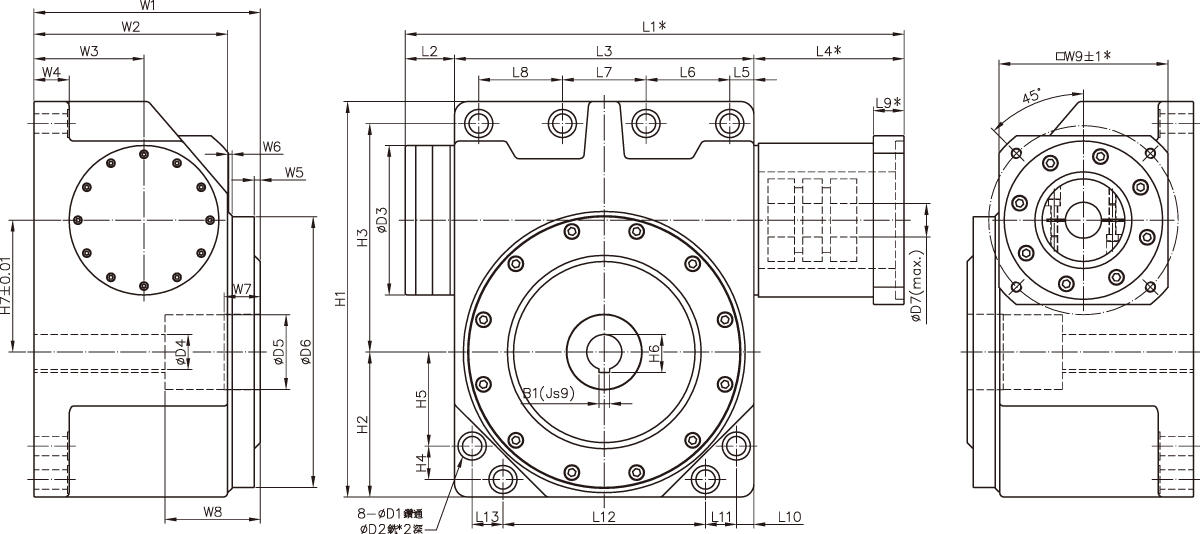

| Frame size |

DWG100L |

DWG125L |

DWG150L |

DWG175L |

DWG200L |

| B1 |

12 |

14 |

16 |

20 |

22 |

| D1 |

13.5 |

17.5 |

22 |

26 |

26 |

| D2 |

20 |

26 |

32 |

39 |

39 |

| D3 |

145 |

155 |

170 |

235 |

245 |

| D4 |

40 |

45 |

50 |

75 |

80 |

| D5 |

- |

75 |

85 |

95 |

115 |

| D6 |

226 |

267 |

308 |

361 |

407 |

| D7(max.) |

35 |

38 |

42 |

42 |

45 |

| H1 |

330 |

390 |

450 |

530 |

605 |

| H2 |

130 |

150 |

165 |

210 |

230 |

| H3 |

182.5 |

220 |

260 |

290 |

350 |

| H4 |

24.3 |

28 |

38 |

60 |

45 |

| H5 |

88.4 |

102.2 |

107 |

120 |

155 |

| H6 |

43.3 |

48.8 |

54.3 |

79.9 |

85.4 |

| H7 |

100 |

125 |

150 |

175 |

200 |

| ※L1 |

489 |

541 |

566.5 |

667.5 |

732.5 |

| L2 |

67 |

81 |

56 |

84.5 |

112.5 |

| L3 |

251 |

280 |

340 |

410 |

430 |

| L4 |

171 |

180 |

170.5 |

173 |

190 |

| L5 |

28 |

20 |

27.5 |

65 |

27.5 |

| L6 |

65 |

60 |

95 |

90 |

125 |

| L7 |

65 |

120 |

95 |

100 |

125 |

| L8 |

65 |

60 |

95 |

90 |

125 |

| ※L9 |

35 |

33 |

35 |

35 |

40 |

| L10 |

17.2 |

18.2 |

20 |

30 |

30 |

| L11 |

26.5 |

30.6 |

35 |

35 |

45 |

| L12 |

157.7 |

182.4 |

230 |

280 |

280 |

| L13 |

26.5 |

30.6 |

35 |

35 |

45 |

| W1 |

183 |

219 |

257 |

291 |

334 |

| W2 |

156.5 |

189.5 |

220 |

256 |

295 |

| W3 |

85.75 |

103 |

125 |

138 |

160 |

| W4 |

30.5 |

34.5 |

40 |

45 |

45 |

| W5 |

3.5 |

5 |

7 |

- |

- |

| W6 |

3 |

3 |

5 |

5 |

7 |

| W7 |

- |

27.5 |

41 |

32.3 |

35 |

| W8 |

- |

72.5 |

108 |

94.3 |

110 |

※Actual dimensions may vary from different servo motors.

We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

B1﹑D4﹑D5﹑H6﹑W7﹑W8 are customizable. Contact us for more details.