Rigorous and perfect quality assurance system, based on international ISO standards

SunUs quality assurance system supervises and controls each machine's quality and stability and uses not only high-standard production equipment and processes but also scientific and technological inspection equipment and instruments in order to maintain the entire procedure, from the beginning of raw materials arriving the plant into a final product until being sold, is regulated by world-recognized international ISO standards. The HG series has been recognized by the Taiwan Excellence Awards, so that SunUs products can meet world standards, and SunUs customers receive the best quality and service.

the best quality products offer and the most satisfactory after-sales service

the best quality products offer and the most satisfactory after-sales service

ODM design and manufacture of planetary gear reducers, reducer transmission mechanisms, and precision transmission components so on; and OEM manufacture

We have been innovating reducers and services continuously, and, according to different customer needs and mechanisms, SunUs provides differentiated product functionality and design to assist all customers in solving problems and achieving goals.

Manufacture

Manufacture control

Manufacture control

Supplier management and assessment and both integration mechanism will depend on product requirements and supplier quality capabilities. Superior suppliers and third-party vendors will be picked up, and so will the supplier roll, related business transaction records, and quality inspection sheet be set up. On the other hand, SunUs will provide relevant information on technical issues.

Raw material control

Raw material control

The product structural characteristics will be considered while in design; and options of raw material to manufacture are both many and essential, and so do whether or not they meet the applicability. Then selected suppliers will be asked to provide excellent materials.

Manufacture control

Raw material control

Raw material control

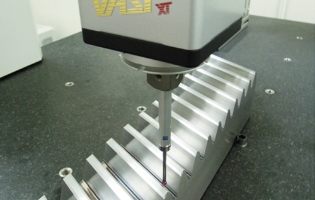

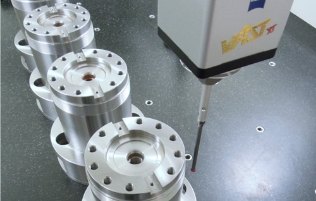

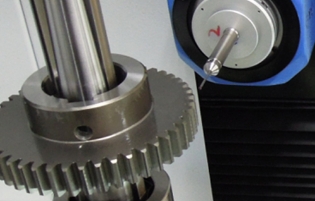

Strict quality control, QC, has been built up from the time the material enters the factory until the product is delivered to the customer. All Incoming Quality Control (IQC), In Process Quality Control (IPQC), and Outgoing Quality Control (OQC) will be conducted through precision inspection equipment, including Swiss two-dimensional coordinate-measuring machine, German Zeiss three-dimensional coordinate-measuring machine, Rockwell hardness tester, automatic gear profile machine from German and Japan, and so forth. SunUs professional quality engineers (QE) will make the most stringent check for quality; our perfect inspection standards and processes are the high-quality guarantee.

Semi-finished product assembly and finished testing

Autonomous inspection

The personnel in manufacture process should refer to control focuses and quality standards of the Work Instruction to carry out independent inspection for the work in process.

In process quality control

The QE inspects WIP during manufacturing process according to the inspection standards of IPQC record sheet.

Product inspection

All product testing must pass the acceptance criteria before shipment to ensure quality.