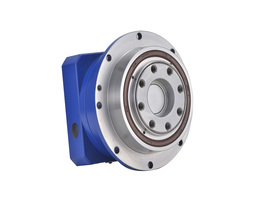

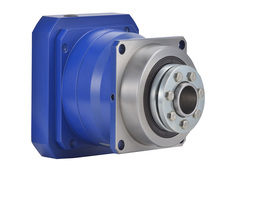

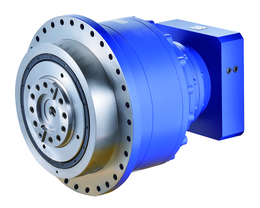

PG universal

| Precision Level |

|

|---|---|

| Torsional Rigidity |

|

| Price Range |

|

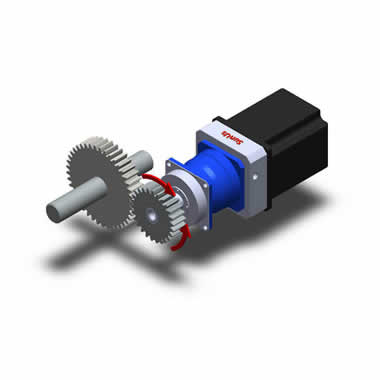

- Industry Applications

- CNC Machine Tools

- Special Purpose Machines (SPMs)

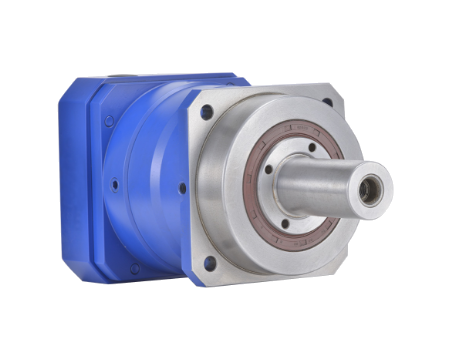

- Precision ground gears have smooth surfaces and accurate profiles

- The series case and inner ring gear, designed into one structure, are made of special stable alloy steel.

- For the precision of ground gears, the well-designed structure and high-duty material of gearbox and bracket.

- For an excellent design, high accuracy, and low moments of inertia.

- For the high standard of ground gears and best-chosen synthetic oil.

- For the professional gear producing experience and the serious quality control of manufacturing processes.

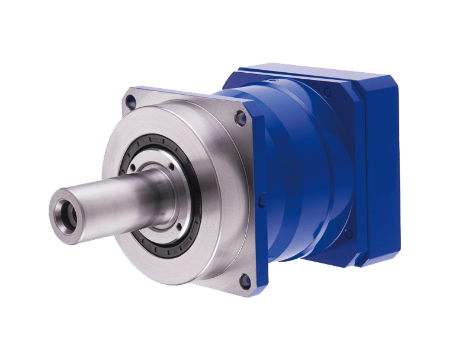

- Precision manufacture under quality control:

Micro backlash: stage one ≤ 1 arcmin; stage two ≤ 3 arcmins.

Reduced backlash: stage one ≤ 3 arcmins; stage two ≤ 5 arcmins.

Standard backlash: stage one ≤ 5 arcmins; stage two ≤ 7 arcmins.

- Gears are made of a quality alloy of nickel, chrome, and molybdenum steel, and produced with deep carburizing and hardening treatment. Gear surfaces under accurate grind feature better rigid, smooth, and wear resistance.

- Premium German-made synthetic oil, flowable better and including anti-ultra-pressure additive, is used in lubrication and protection of all components in the gearbox. Oil change is never required.

- High-grading oil seals, stable and both heat and wear-resistant, are in use to serve well airtightness.

- For the modular input bushing and the changeable connection plate according to the customer's brand of servo-motor.

PG Technical Data (1-stage) Ratio 3/4/5/6/7/8/10

| Specifications | Ratios | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 3 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 4 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 5 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 6 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 7 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 8 | 33 | 91 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 10 | 32 | 77 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| Emergency Stop Torque(2) T2Not | Nm | 3 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 4 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 5 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 6 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 7 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 8 | 77 | 250 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 10 | 75 | 200 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| Nominal Outout Torque T2N | Nm | 3 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 4 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 5 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 6 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 7 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 8 | 18 | 64 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 10 | 15 | 43 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| Nominal Input Speed n1N | rpm | 3 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 |

| 4 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 5 | 3300 | 3000 | 2600 | 2300 | 2200 | 1800 | 1500 | 1200 | 1100 | ||

| 6 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 7 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 8 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| 10 | 4000 | 3200 | 2900 | 2700 | 2700 | 2500 | 2400 | 1700 | 1600 | ||

| Maximum Input Speed n1Max | rpm | 3 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 |

| 4 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 5 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 6 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 7 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 8 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| 10 | 6000 | 6000 | 4500 | 4000 | 3600 | 3200 | 3000 | 2500 | 2200 | ||

| Radial Load(3) Frmax | N | 3 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 4 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 5 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 6 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 7 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 8 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 10 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| Axial Load(3) Famax | N | 3 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 4 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 5 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 6 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 7 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 8 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 10 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| Micro Backlash | arcmin | 3 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 4 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 5 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 6 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 7 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 8 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| 10 | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ||

| Reduced Backlash | arcmin | 3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 |

| 4 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 5 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 6 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 7 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 8 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| 10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤2 | ≤2 | ≤2 | ||

| Standard Backlash | arcmin | 3 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 4 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 6 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 7 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 8 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| Torsional Rigidity | Nm/arcmin | 3 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 4 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 5 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 6 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 7 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 8 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 10 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| Efficiency with Full Load | % | 3 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 |

| 4 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 5 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 6 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 7 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 8 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| 10 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ≥97 | ||

| Service Life LH2 | h | 3 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 4 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 5 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 6 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 7 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 8 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 10 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Weight | kg | 3 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 |

| 4 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 5 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 6 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 7 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 8 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| 10 | 2.5 | 4 | 8 | 12 | 16 | 23 | 33 | 56 | 85 | ||

| Noise Level(4) | dB | 3 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 4 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 5 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 6 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 7 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 8 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 10 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| Permissble Gear Reducer Temp. | °C | 3 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 4 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 5 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 6 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 7 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 8 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 10 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Protection Class | 3 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 4 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 5 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 6 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 7 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 8 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 10 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Lubrication | 3 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 4 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 5 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 6 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 7 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 8 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 10 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Mass Moments of Inertia | kg‧cm2 | 3 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 16.22 | 37.40 | 72.10 | 140.80 |

| 4 | 0.30 | 0.60 | 4.22 | 5.09 | 9.10 | 12.90 | 29.80 | 50.50 | 97.10 | ||

| 5 | 0.29 | 0.59 | 4.13 | 4.93 | 8.85 | 12.30 | 28.43 | 45.20 | 87.40 | ||

| 6 | 0.29 | 0.58 | 4.08 | 4.89 | 8.63 | 11.88 | 27.67 | 44.10 | 84.50 | ||

| 7 | 0.28 | 0.58 | 4.05 | 4.83 | 8.50 | 11.83 | 27.55 | 42.60 | 81.40 | ||

| 8 | 0.28 | 0.57 | 4.04 | 4.83 | 8.48 | 11.80 | 27.47 | 42.20 | 80.10 | ||

| 10 | 0.27 | 0.57 | 4.04 | 4.81 | 8.46 | 11.70 | 27.45 | 41.90 | 79.80 | ||

Note (1) Data are measured at the frequency under 1000 times per hour. Contact us if your data are beyond the presented table above.

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 rpm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm; 1-meter distance and free load operation.

• If any customized ratios are unavailable from above, please contact us for more.

• Consult us if your mode is continuous operation.

PG Technical Data (2-stage) Ratio 12~100

| Specifications | Ratios | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Output Torque (1) T2B | Nm | 12 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 |

| 15 | 25 | 90 | 202 | 330 | 440 | 735 | 1055 | 1750 | 3600 | ||

| 16 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 20 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 25 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 28 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 30 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 35 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 40 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 50 | 47 | 115 | 270 | 350 | 510 | 810 | 1300 | 2600 | 4100 | ||

| 60 | 40 | 103 | 250 | 340 | 445 | 730 | 1180 | 2150 | 3780 | ||

| 70 | 40 | 100 | 240 | 310 | 440 | 700 | 1130 | 1680 | 3500 | ||

| 80 | 33 | 91 | 215 | 285 | 410 | 650 | 1040 | 1600 | 3300 | ||

| 100 | 32 | 77 | 190 | 245 | 340 | 500 | 900 | 1500 | 2700 | ||

| Emergency Stop Torque(2) T2Not | Nm | 12 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 |

| 15 | 60 | 240 | 630 | 800 | 1100 | 1700 | 3000 | 6200 | 9000 | ||

| 16 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 20 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 25 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 28 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 30 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 35 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 40 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 50 | 100 | 310 | 710 | 900 | 1260 | 1850 | 3250 | 6480 | 9500 | ||

| 60 | 85 | 280 | 650 | 800 | 1120 | 1700 | 2880 | 5500 | 8950 | ||

| 70 | 85 | 270 | 625 | 780 | 1100 | 1600 | 2800 | 5000 | 8650 | ||

| 80 | 77 | 250 | 550 | 690 | 1025 | 1470 | 2560 | 4600 | 7200 | ||

| 100 | 75 | 200 | 500 | 650 | 900 | 1250 | 2220 | 3900 | 6800 | ||

| Nominal Outout Torque T2N | Nm | 12 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 |

| 15 | 15 | 60 | 135 | 195 | 315 | 500 | 880 | 1200 | 2000 | ||

| 16 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 20 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 25 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 28 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 30 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 35 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 40 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 50 | 26 | 78 | 185 | 240 | 340 | 550 | 1100 | 1900 | 2600 | ||

| 60 | 23 | 70 | 155 | 210 | 320 | 460 | 845 | 1580 | 2250 | ||

| 70 | 23 | 65 | 125 | 180 | 315 | 430 | 820 | 1050 | 1700 | ||

| 80 | 18 | 64 | 120 | 175 | 293 | 410 | 755 | 1000 | 1660 | ||

| 100 | 15 | 43 | 115 | 160 | 220 | 350 | 650 | 950 | 1550 | ||

| Nominal Input Speed n1N | rpm | 12 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 |

| 15 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 16 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 20 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 25 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 28 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 30 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 35 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 40 | 4400 | 3600 | 3200 | 3000 | 3000 | 2900 | 2800 | 2200 | 2000 | ||

| 50 | 4800 | 3900 | 3600 | 3300 | 3200 | 3100 | 3000 | 2400 | 2200 | ||

| 60 | 4800 | 3900 | 3600 | 3300 | 3200 | 3100 | 3000 | 1580 | 2200 | ||

| 70 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 80 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| 100 | 5500 | 4500 | 4200 | 3900 | 3500 | 3300 | 3200 | 2800 | 2400 | ||

| Maximum Input Speed n1Max | rpm | 12 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 |

| 15 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 16 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 20 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 25 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 28 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 30 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 35 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 40 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 50 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 60 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 70 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 80 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| 100 | 6000 | 6000 | 4500 | 4000 | 3600 | 3600 | 3600 | 3000 | 3000 | ||

| Radial Load(3) Frmax | N | 12 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 |

| 15 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 16 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 20 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 25 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 28 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 30 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 35 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 40 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 50 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 60 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 70 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 80 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| 100 | 2600 | 3800 | 6000 | 7500 | 9000 | 11500 | 14000 | 18000 | 27000 | ||

| Axial Load(3) Famax | N | 12 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 |

| 15 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 16 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 20 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 25 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 28 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 30 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 35 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 40 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 50 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 60 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 70 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 80 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| 100 | 2300 | 3200 | 5400 | 6700 | 9000 | 11300 | 14000 | 18000 | 27000 | ||

| Micro Backlash | arcmin | 12 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 15 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 16 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 20 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 25 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 28 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 30 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 35 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 40 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 50 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 60 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 70 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 80 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 100 | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Reduced Backlash | arcmin | 12 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 |

| 15 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 16 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 20 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 35 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 40 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 50 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 60 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 70 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 80 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| 100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤4 | ≤4 | ≤4 | ||

| Standard Backlash | arcmin | 12 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 |

| 15 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 16 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 20 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 25 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 28 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 30 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 35 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 40 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 50 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 60 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 70 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 80 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| 100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤6 | ≤6 | ||

| Torsional Rigidity | Nm/arcmin | 12 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 |

| 15 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 16 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 20 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 25 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 28 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 30 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 35 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 40 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 50 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 60 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 70 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 80 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| 100 | 3 | 8.5 | 23 | 35 | 50 | 95 | 150 | 220 | 355 | ||

| Efficiency with Full Load | % | 12 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 |

| 15 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 16 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 20 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 25 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 28 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 30 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 35 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 40 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 50 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 60 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 70 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 80 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| 100 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ≥94 | ||

| Service Life LH2 | h | 12 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

| 15 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 16 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 20 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 25 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 28 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 30 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 35 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 40 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 50 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 60 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 70 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 80 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| 100 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | ||

| Weight | kg | 12 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 |

| 15 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 16 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 20 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 25 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 28 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 30 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 35 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 40 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 50 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 60 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 70 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 80 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| 100 | 3.1 | 4.6 | 9.2 | 15.2 | 20.3 | 23.7 | 35.5 | 59 | 87 | ||

| Noise Level(4) | dB | 12 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 |

| 15 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 16 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 20 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 25 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 28 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 30 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 35 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 40 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 50 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 60 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 70 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 80 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| 100 | ≤60 | ≤62 | ≤62 | ≤65 | ≤65 | ≤65 | ≤66 | ≤68 | ≤68 | ||

| Permissble Gear Reducer Temp. | °C | 12 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 |

| 15 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 16 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 20 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 25 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 28 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 30 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 35 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 40 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 50 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 60 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 70 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 80 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| 100 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | -10~+90 | ||

| Protection Class | 12 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | |

| 15 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 16 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 20 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 25 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 28 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 30 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 35 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 50 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 60 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 70 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 80 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| 100 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | IP64 | ||

| Lubrication | 12 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | |

| 15 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 16 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 20 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 25 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 28 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 30 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 35 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 40 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 50 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 60 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 70 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 80 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| 100 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ISO VG220 | ||

| Mass Moments of Inertia | kg‧cm2 | 12 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 |

| 15 | 0.31 | 0.75 | 4.73 | 5.90 | 10.50 | 10.50 | 11.00 | 37.50 | 37.70 | ||

| 16 | 0.30 | 0.60 | 4.20 | 5.09 | 9.00 | 9.30 | 9.30 | 30.00 | 31.00 | ||

| 20 | 0.30 | 0.60 | 4.20 | 5.07 | 9.00 | 9.20 | 9.30 | 30.00 | 31.00 | ||

| 25 | 0.29 | 0.59 | 4.12 | 4.91 | 8.83 | 9.00 | 9.05 | 28.70 | 30.10 | ||

| 28 | 0.30 | 0.59 | 4.20 | 5.07 | 9.00 | 9.20 | 9.20 | 29.90 | 31.00 | ||

| 30 | - | 0.58 | 4.08 | 4.90 | 8.63 | 8.65 | 9.65 | 27.70 | 29.05 | ||

| 35 | 0.30 | 0.58 | 4.12 | 4.91 | 8.82 | 8.90 | 9.03 | 28.80 | 30.08 | ||

| 40 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.50 | 8.52 | 27.70 | 28.70 | ||

| 50 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.70 | ||

| 60 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.52 | 27.70 | 28.55 | ||

| 70 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.49 | 8.50 | 27.70 | 28.50 | ||

| 80 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

| 100 | 0.27 | 0.56 | 4.04 | 4.80 | 8.45 | 8.48 | 8.50 | 27.70 | 28.50 | ||

Note (1) Data are measured at the frequency under 1000 times per hour. Contact us if your data are beyond the presented table above.

Note (2) Operation can be up to 1000 times in product life.

Note (3) Act at the center of output shaft in 100 rpm.

Note (4) Noise is inspected under the condition of ratio 5; input speed 3000 rpm; 1-meter distance and free load operation.

• If any customized ratios are unavailable from above, please contact us for more.

• Consult us if your mode is continuous operation.

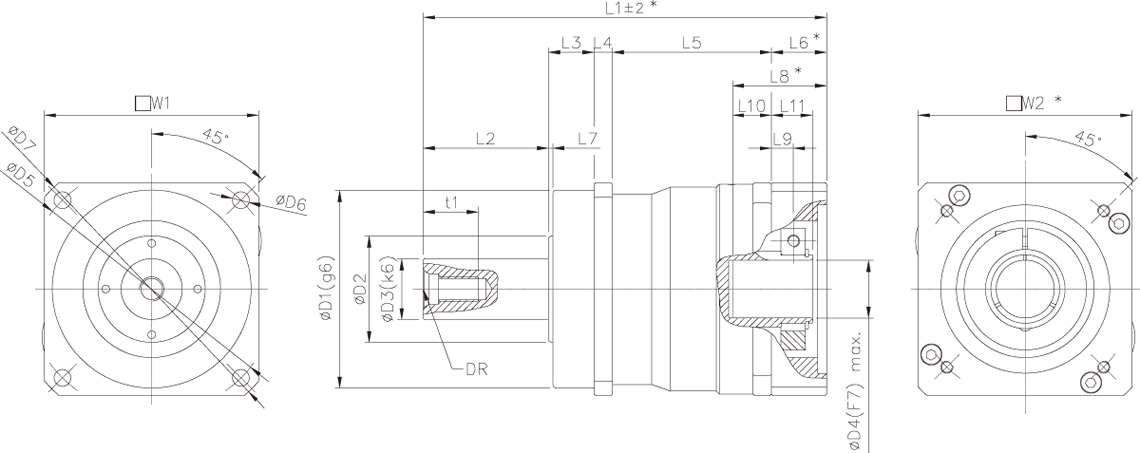

PG Dimensions (1-Stage 3 / 4 / 5 / 6 / 7 / 8 / 10 Ratio)[mm]

| Size | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 |

|---|---|---|---|---|---|---|---|---|---|

| W1 | 62 | 80 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 mln. | 75 | 88 | 118 | 130 | 140 | 175 | 190 | 190 | 240 |

| DR | M5 | M8 | M12 | M12 | M16 | M16 | M20 | M20 | M20 |

| t1 | 12.5 | 19 | 28 | 28 | 36 | 36 | 42 | 42 | 42 |

| D1 (g6) | 60 | 70 | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 30 | 40 | 55 | 60 | 70 | 85 | 95 | 125 | 140 |

| D3 (k6) | 16 | 22 | 32 | 35 | 40 | 50 | 55 | 75 | 85 |

| D4 (F7) max. | 14 | 19 | 32 | 35 | 38 | 42 | 48 | 55 | 60 |

| D5 | 68 | 85 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D6 | 5.5 | 6.6 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D7 | 79 | 103 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 135.5 | 161 | 213.5 | 232.5 | 262.5 | 266.5 | 297 | 349.5 | 422 |

| L2 | 28 | 36 | 58 | 70 | 82 | 82 | 82 | 105 | 130 |

| L3 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 38 | 40 |

| L4 | 6 | 7 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 60.5 | 73 | 87.5 | 93 | 104 | 106.5 | 122 | 139.5 | 154 |

| ※L6 min. | 22.5 | 25 | 28 | 28.5 | 34.5 | 34.5 | 48 | 50 | 78 |

| L7 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| ※L8 min. | 33 | 40 | 52 | 52 | 60 | 60 | 82 | 82 | 110 |

| L9 | 10 | 11.5 | 11.5 | 12.8 | 14.3 | 14.3 | 17.8 | 18.5 | 22.5 |

| L10 | 12 | 15 | 24 | 24 | 25.5 | 25.5 | 34 | 32 | 32 |

| L11 | 18 | 20 | 22 | 24.5 | 27 | 27 | 33.5 | 34.5 | 41 |

※Actual dimensions marked above may vary from different servo motors.

We have persistently invested in R&D and made every effort to maintain the correctedness of the specification above. If there is any discrepancy between the data and real dimensions, please refer to our actual products and contact us for specific dimensions.

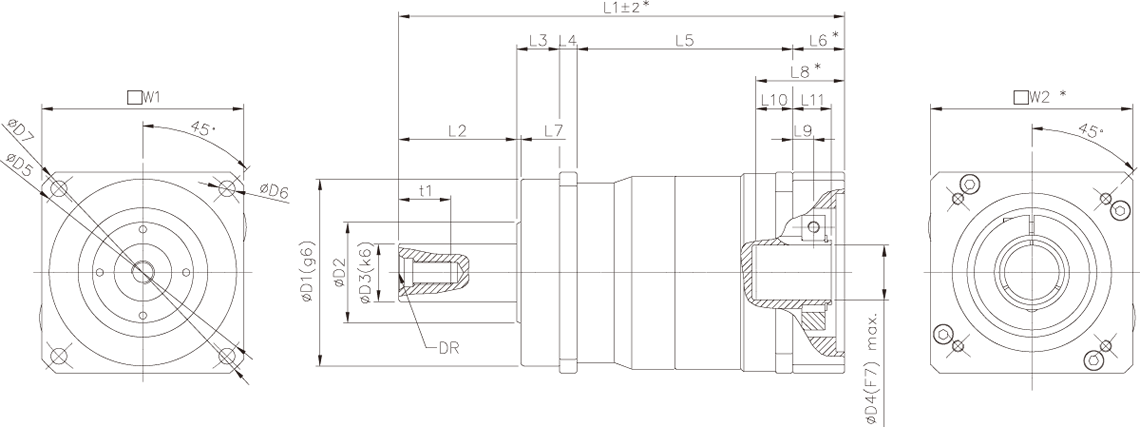

PG Dimensions (2-Stage 12 ~ 100 Ratio)[mm]

| Size | PG060 | PG080 | PG100 | PG120 | PG140 | PG160 | PG180 | PG210 | PG240 |

|---|---|---|---|---|---|---|---|---|---|

| W1 | 62 | 80 | 100 | 120 | 140 | 160 | 182 | 210 | 240 |

| ※W2 mln. | 72 | 88 | 118 | 130 | 140 | 140 | 140 | 190 | 190 |

| DR | M5 | M8 | M12 | M12 | M16 | M16 | M20 | M20 | M20 |

| t1 | 12.5 | 19 | 28 | 28 | 36 | 36 | 42 | 42 | 42 |

| D1 (g6) | 60 | 70 | 90 | 110 | 130 | 145 | 160 | 180 | 200 |

| D2 | 30 | 40 | 55 | 60 | 70 | 85 | 95 | 125 | 140 |

| D3 (k6) | 16 | 22 | 32 | 35 | 40 | 50 | 55 | 75 | 85 |

| D4 (F7) max. | 14 | 19 | 32 | 35 | 38 | 38 | 38 | 48 | 48 |

| D5 | 68 | 85 | 120 | 130 | 165 | 190 | 215 | 250 | 290 |

| D6 | 5.5 | 6.6 | 9 | 9 | 11 | 13 | 13 | 17 | 17 |

| D7 | 79 | 103 | 135 | 155 | 185 | 215 | 240 | 279 | 320 |

| ※L1 | 157.5 | 193 | 252 | 272.5 | 305.5 | 309.5 | 318 | 395.5 | 440 |

| L2 | 28 | 36 | 58 | 70 | 82 | 82 | 82 | 105 | 130 |

| L3 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 38 | 40 |

| L4 | 6 | 7 | 10 | 11 | 12 | 13.5 | 15 | 17 | 20 |

| L5 | 82.5 | 105 | 126 | 133 | 147 | 149.5 | 156.5 | 187.5 | 202 |

| ※L6 min. | 22.5 | 25 | 28 | 28.5 | 34.5 | 34.5 | 34.5 | 48 | 48 |

| L7 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| ※L8 min. | 33 | 40 | 52 | 52 | 60 | 60 | 60 | 82 | 82 |

| L9 | 10 | 11.5 | 11.5 | 12.8 | 14.3 | 14.3 | 14.3 | 17.8 | 17.8 |

| L10 | 12 | 15 | 24 | 24 | 25.5 | 25.5 | 25.5 | 34 | 34 |

| L11 | 18 | 20 | 22 | 24.5 | 27 | 27 | 27 | 33.5 | 33.5 |

※Actual dimensions marked above may vary from different servo motors.

We have persistently invested in R&D and made every effort to maintain the correctedness of the specification above. If there is any discrepancy between the data and real dimensions, please refer to our actual products and contact us for specific dimensions.

- CNC Gantry Milling Machine / CNC Gantry Grinding Machine

- CNC Integrated Processing Machine / CNC Deephole Processing Machine

- CNC Floor Boring Machine / CNC Drilling Machine

- CNC Gantry Planing Mill / CNC Punching Machine

- CNC Heavy Duty Lathe (Horizontal or Vertical Spindle

- Packaging Machinery / Print Machine / Tapping machine

- Textile Machinery / Tube Bending Machine / CNC Press

- Woodworking Machine / Blow Molding Machine / Engraving Machine

- Filling Machine / Injection Molding Machine / Spring Machine

- Laser Cutting Machine / Laser Welding Machine

- Semiconductor Machinery and Equipment / Photoelectric Panel Industry

- Gantry Loader / Automated Storage and Retrieval System

- Medical Industry / Metal Surface Treatment Equipment

- Automatic Mechanical Device with Servo Motor Collocation

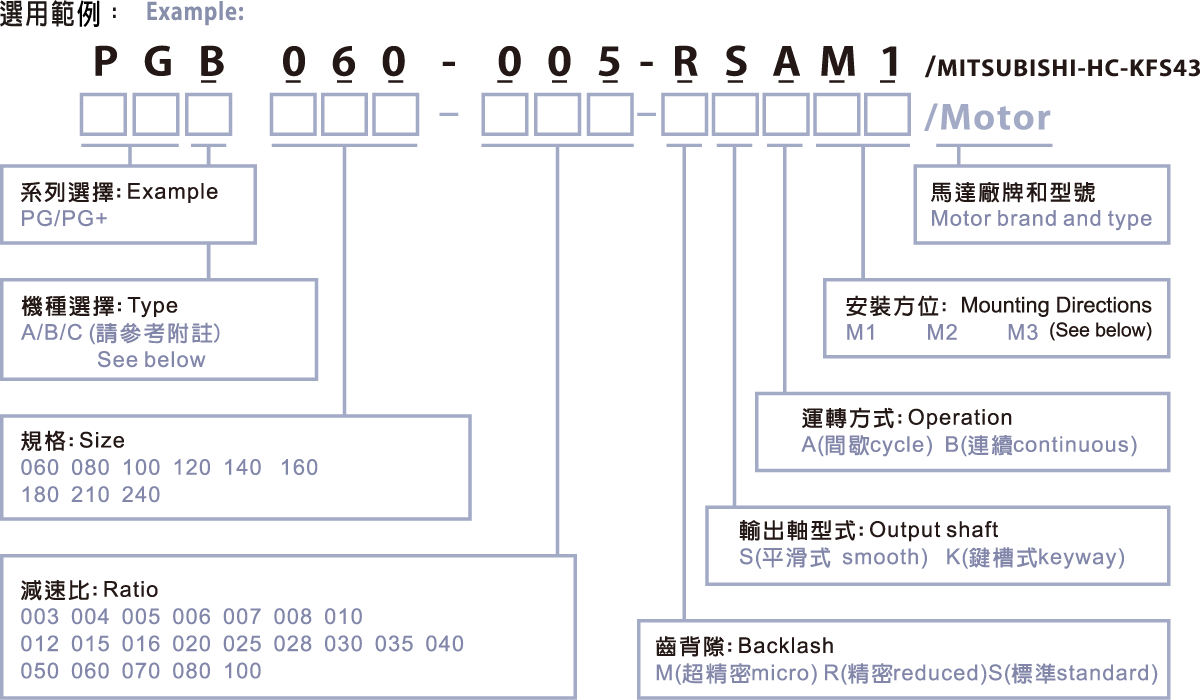

Type :

A : Applied to machine tools, requiring huge torque and high accuracy and operating more than 10 hours continually daily, in military, aerospace, or semiconductor industries.

B : Applied to factory automation related industries , general special purpose machine, gantry loader, or machine tools.

C : Applied to automation or machine tools, operating discontinuously and infrequently.

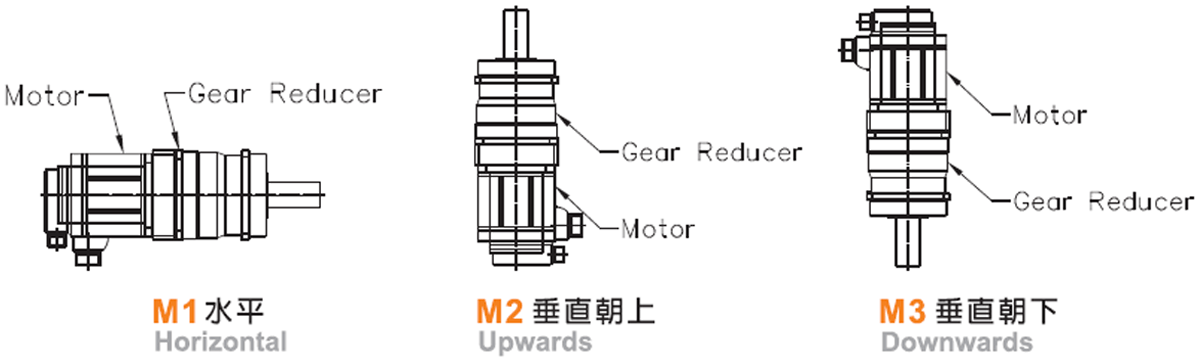

Mounting positions

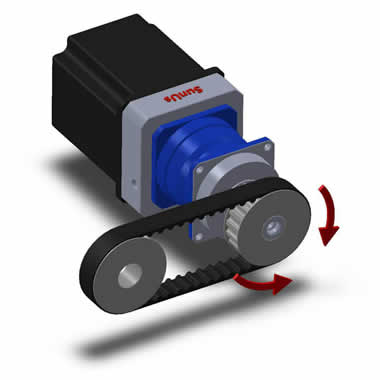

Pulley

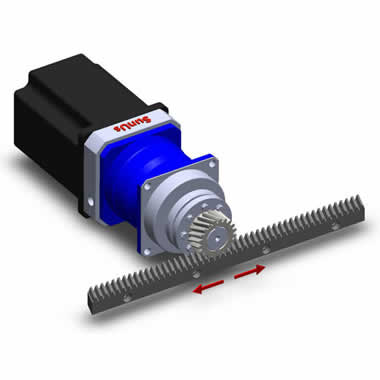

Rack&Pinion

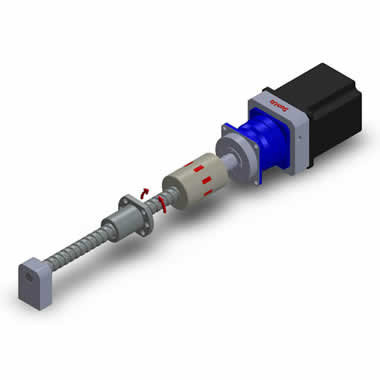

Ball screw